onsemi has introduced its latest generation of silicon and silicon carbide hybrid Power Integrated Modules (PIMs) in the F5BP package, designed to enhance the power output of utility-scale solar string inverters and energy storage system (ESS) applications. These new modules deliver increased power density and efficiency within the same footprint as their predecessors, allowing a solar inverter to increase its total system power from 300kW to 350kW. This improvement can lead to significant energy savings, with a one-gigawatt (GW) capacity utility-scale solar farm potentially saving nearly two megawatts (MW) per hour—enough to power more than 700 homes annually. The enhanced efficiency also means fewer modules are required to reach the same power levels, which could reduce power device component costs by over 25%.

onsemi has introduced its latest generation of silicon and silicon carbide hybrid Power Integrated Modules (PIMs) in the F5BP package, designed to enhance the power output of utility-scale solar string inverters and energy storage system (ESS) applications. These new modules deliver increased power density and efficiency within the same footprint as their predecessors, allowing a solar inverter to increase its total system power from 300kW to 350kW. This improvement can lead to significant energy savings, with a one-gigawatt (GW) capacity utility-scale solar farm potentially saving nearly two megawatts (MW) per hour—enough to power more than 700 homes annually. The enhanced efficiency also means fewer modules are required to reach the same power levels, which could reduce power device component costs by over 25%.As solar power continues to offer the lowest levelized cost of energy (LCOE), it is increasingly preferred for renewable power generation globally. However, due to the variable nature of solar energy, utility operators are pairing it with large-scale battery energy storage systems (BESS) to maintain consistent energy flow to the grid. To support these combined systems, both manufacturers and utilities require solutions that maximize efficiency and ensure reliable power conversion. Even a small efficiency gain of 0.1% can result in substantial annual savings—up to a quarter of a million dollars per gigawatt of installed capacity.

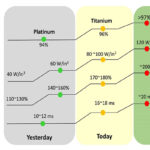

The F5BP-PIMs integrate a 1050V FS7 IGBT and a 1200V D3 EliteSiC diode, creating a robust foundation for high voltage and high current power conversion. These components are engineered to minimize power dissipation and enhance reliability. The FS7 IGBTs reduce turn-off losses and cut switching losses by up to 8%, while the EliteSiC diodes offer improved switching performance and a 15% reduction in voltage flicker (VF) compared to earlier models.

These PIMs incorporate an I-type Neutral Point Clamp (INPC) for the inverter module and a flying capacitor topology for the boost module. An optimized electrical layout and advanced Direct Bonded Copper (DBC) substrates are employed to reduce stray inductance and thermal resistance. Additionally, a copper baseplate further lowers thermal resistance to the heat sink by 9.3%, ensuring effective cooling under high operational loads. This advanced thermal management supports the modules’ efficiency and longevity, making them well-suited for applications requiring consistent and reliable power delivery.

Leave a Reply