With the development of Energy Star Titanium efficiency power supplies, the power electronics industry has met the challenges of reducing data center energy consumption and supporting a greener society. What were those challenges, and is there a path to “more than Titanium” power supplies?

High-efficiency power factor correction (PFC) and high-efficiency dc-dc conversion were key challenges when developing titanium-efficient ac-dc power supplies. The benefits go beyond efficiency. This article briefly examines the benefits of using Titanium power supplies, reviews the challenges that have been met, and peers toward “more than Titanium.”

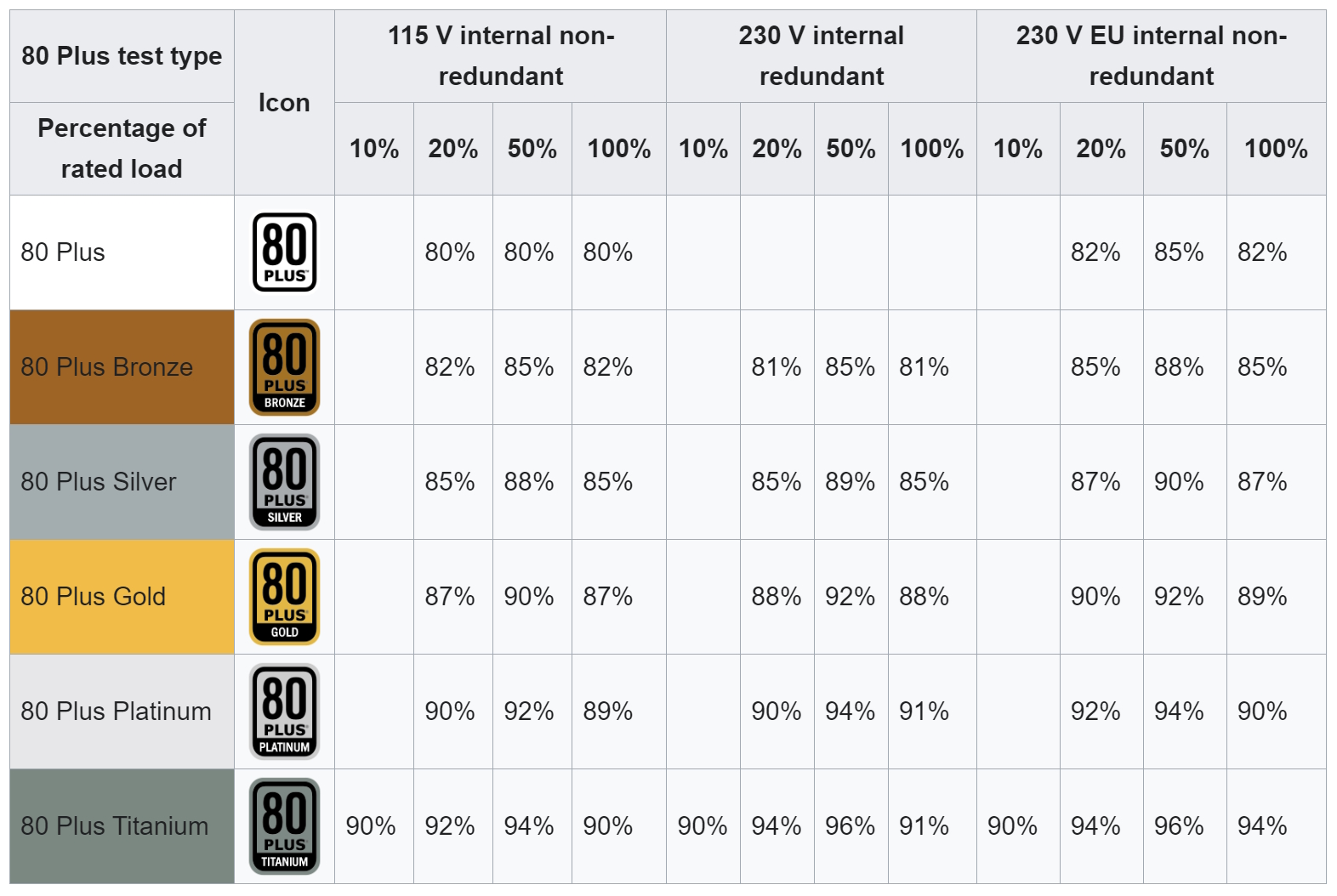

The lower levels of 80 Plus efficiency are much better than those of previous generations of power supplies. They significantly improve the cost/benefit ratio for consumer devices not in constant use.

In data centers, the power supplies are usually operated 24/7, making efficiency a key cost consideration. Higher efficiency results in energy savings in the power supply and generates less heat load for the cooling system to handle, increasing data center power usage efficiency (PUE). Titanium power supplies support a variety of higher power-density data center solutions (Table 1).

In addition to efficiency requirements, Titanium power supplies must deliver a high power factor (PF) at a light load. The Platinum rating requires a PF of at least 0.95 at 50% load, while the titanium level demands a PF of at least 0.95 at 20% load, a higher hurdle to clear.

A highly efficient active PFC is required to meet the combined efficiency and PF requirements for Titanium power supplies. A totem pole topology is often used for the PFC section in these designs.

Si devices are not a good option. The design requires high-voltage devices. Si devices have a large reverse recovery charge (Qrr) that limits them from being used in critical conduction mode. They are only useful for relatively low power levels due to electromagnetic interference (EMI) challenges.

SiC or GaN can support the high efficiency needed, enabling a totem pole PFC to deliver high PF across a more comprehensive power range. These devices offer fast switching speeds and low on resistance. SiC devices have a low Qrr, while GaN devices have zero Qrr.

What about silicon with digital control?

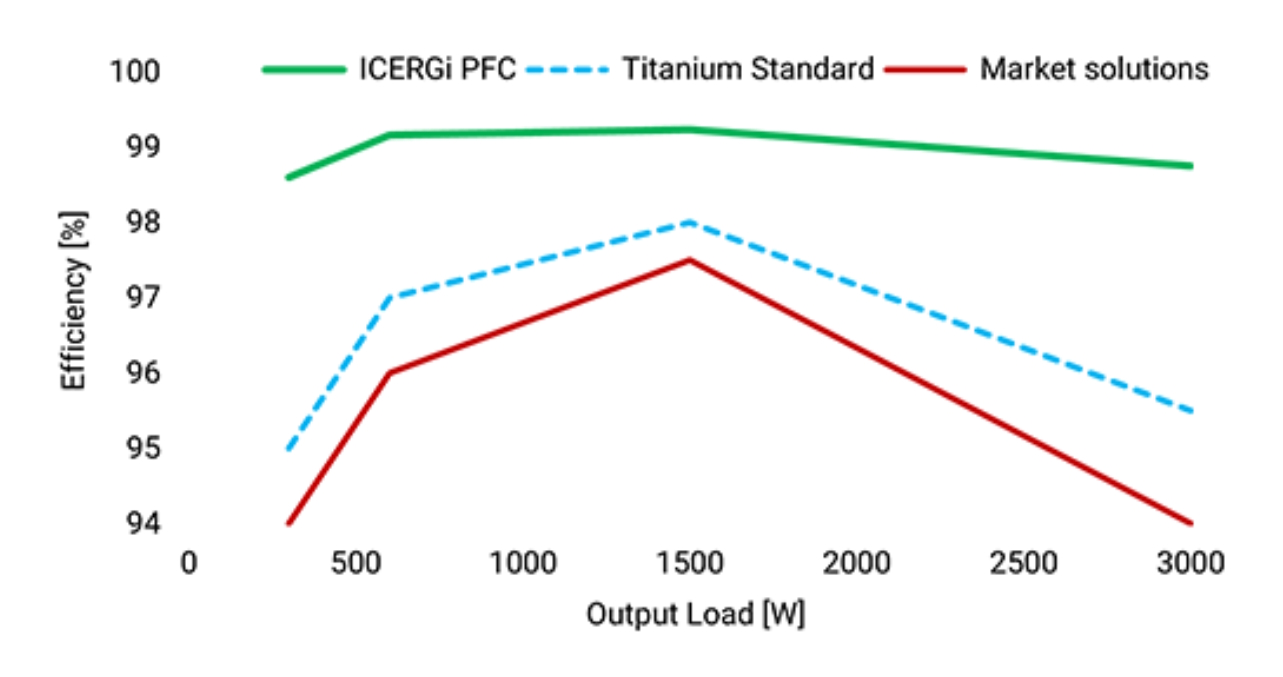

Conventional totem pole PFCs require high-voltage Si FETs, whose high Qrr makes the design unsuitable. However, with a multilevel topology, lower-voltage FETs with much lower Qrr can be used. Adding an ARM-based digital controller can produce a Si-based PFC section that delivers 99% efficiency and can support the demands of Titanium power supplies (Figure 1).

DC-DC efficiency

For the dc-dc section that converts the PFC 400 Vdc bus to 48 or 12 Vdc, GaN FETs are often the preferred choice. Their lower conduction losses and low gate drive power deliver high efficiency. Add the use of GaN for synchronous rectification, and the resulting power supply can meet the 96% efficiency demanded for Titanium recognition.

GaN FETs also parallel better than Si devices. The low output charge (Qoss) leads to higher frequency performance. They switch many times faster and are smaller. GaN FETs are used in various dc-dc topologies like LLC or phase-shifted full bridge (PSFB).

Energy Star isn’t the only game in town

Energy Star is a foundational standard, but there are other considerations. For example, the Modular Hardware System Common Redundant Power Supply (M-CRPS) platform from the Open Compute Project (OCP) defines a 60 x 185 mm x 1U (40 mm) form factor for data center power supplies. A 1,800 W Titanium power supply has been developed in the M-CRPS envelope. It has an average efficiency of 93.85% and a PF that ranges from 0.9125 at 5% load to 0.9973 at full load.

More than Titanium

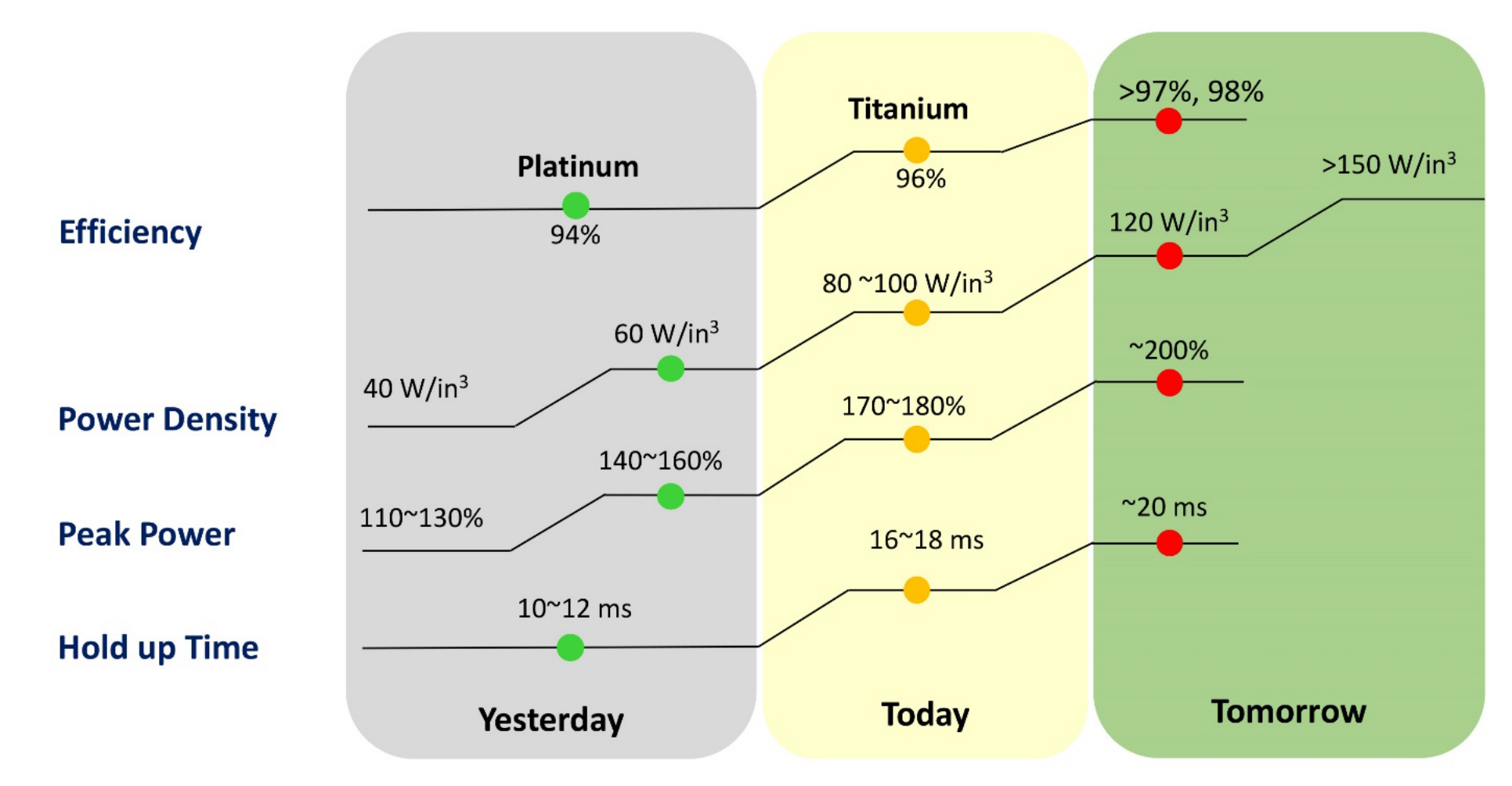

Today’s Titanium power supplies are great. But they’re not the final word. A roadmap to more than Titanium has begun to be formulated (Figure 2).

Summary

While the basic job is done, there’s still much to do to improve data center energy efficiency and support a greener society. What will the next data center power supply efficiency requirement be? And what will it be called? “Zirconium” sounds good. But whatever it is, it will not be the last word in efficiency.

References

2.2 kW Bridgeless Totem-Pole PFC, Wolfspeed

80 PLUS: Why You Need Titanium Power Supplies in Your Data Center, Bel Power

2024 Best Practice Guidelines for the EU Code of Conduct on Data Centre Energy Efficiency, European Energy Efficiency Platform (E3P)

100W/in3 Data Center Power Supply, Infineon

Advanced Energy Previews Industry’s First Titanium Efficiency M-CRPS Power Supply at OCP Global Summit, Advanced Energy

Data Center GaN Applications: AC/DC Power Conversion, Efficient Powe Conversion

GaN FETs help push 80 PLUS Titanium grade, Nexperia

High-Density Power for the AI Revolution, Navitas Semiconductor

Multilevel Technologies The “Next Step” After Interleaving Approaches, ICERGi

What is 80 PLUS certification program?, CLEAResult

Leave a Reply