By Shao Zhang, Qorvo

Understanding the differences between trapezoidal, sinusoidal, and field-oriented control can help engineers understand the value of Field Oriented Control (FOC) and the choices available to optimize their designs.

BLDC motors can be smaller, lighter, and quieter than traditional brushed DC motors while enhancing the reliability and energy efficiency of consumer, industrial, automotive, and medical applications. Their brushless construction simplifies equipment design and maintenance by eliminating concerns like mechanical wear, conductive dust, audible noise, and electric arcing.

Control strategies ranging from basic trapezoidal control to smoother sinusoidal control and field-oriented control (FOC) let engineers choose various options to balance complexity and cost against performance and controllability.

Six-step or trapezoidal control

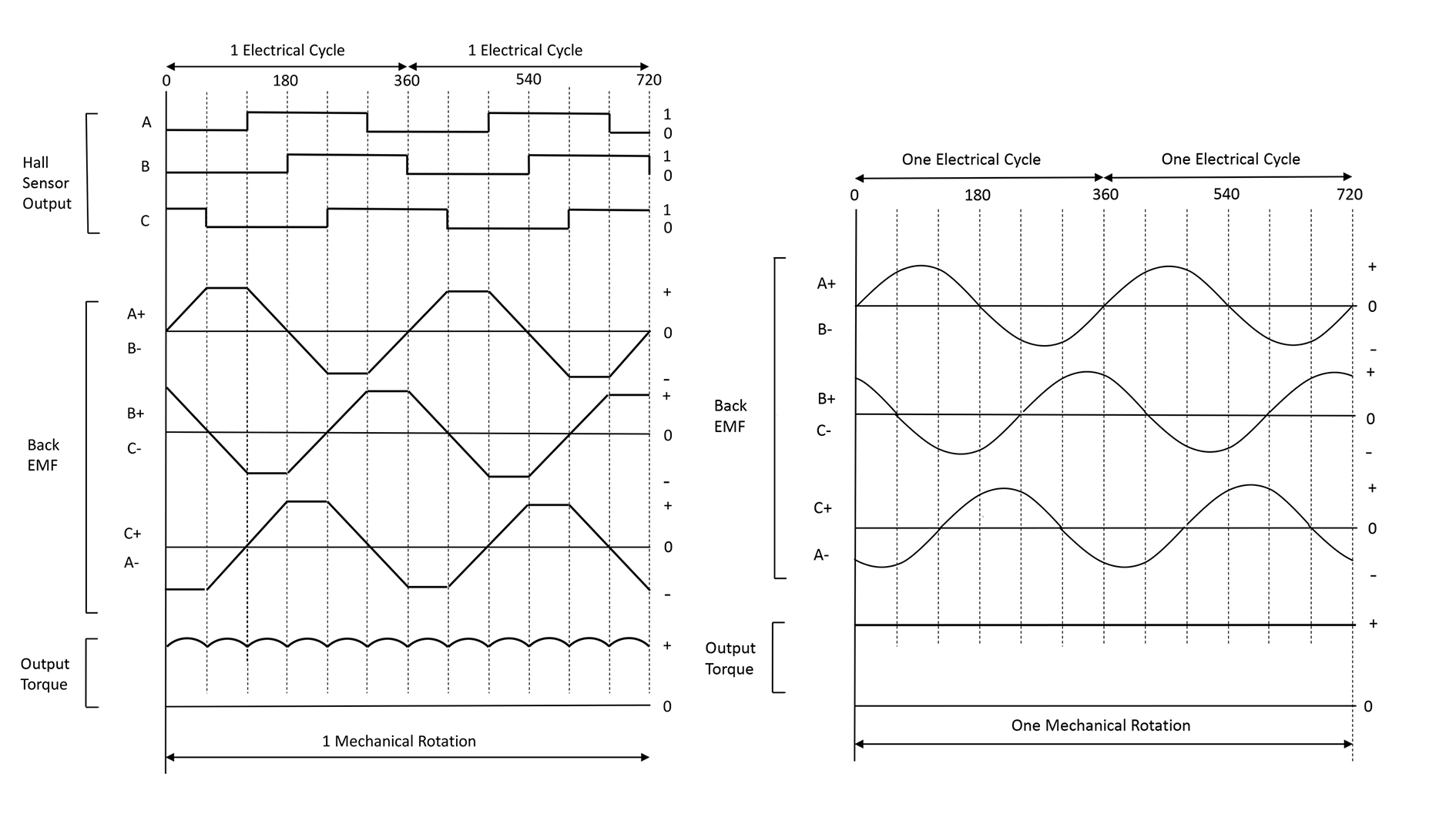

Sequentially energizing the three stator windings using a simplistic “on-off” excitation acts on the static magnetic field of the permanent magnet in the rotor, causing it to rotate. The cycle comprises six pulses applied to each winding to perform one revolution. The waveforms are relatively easy to generate and result in a trapezoidal back emf, as shown on the left of Figure 1. However, the force on the rotor is not purely in a tangential direction, which would be ideal to ensure continuous maximum torque. There is a periodic radial component as the motor rotates that reduces efficiency and causes wear, heating, and so-called “torque ripple.”

Sinusoidal and field-oriented control

Applying sinusoidal excitation can theoretically produce a smoothly rotating field that is always perpendicular to the field of the rotor magnet, resulting in consistent torque, as seen on the right of Figure 1. In practice, effects such as winding inductance and back EMF cause a phase shift in the resulting current and field that prevents simple sinusoidal control from delivering smooth and accurate control.

Field-oriented control (FOC) dynamically corrects the stator field amplitude and direction to achieve the torque and speed commanded by the application. The algorithm calculates the optimum winding current according to the instantaneous measured rotor position.

Field-oriented control to maximize torque

In principle, FOC controls the AC excitation current to keep the angle of the resulting field always perpendicular to the field of the rotor magnet. This produces the highest torque, eliminates torque ripple, maximizes efficiency, and minimizes mechanical wear by removing the radial load on the bearing.

The stator winding currents and consequent field intensity and direction can be represented as three rotating vectors 120 degrees apart in a common static frame. To minimize torque ripple and maximize efficiency, these currents, IU, IV, and IW, must be balanced such that their net sum is zero. FOC aims to achieve this balance, beginning by applying the ‘Clarke’ transformation. This simplifies the currents into two rotating vectors of amplitude Iα and Iβ, 90 degrees apart in a static frame:

Converting these vectors into static components, ID (direct) and IQ (quadrature), in a rotating reference plane permits correlating them with the position of the rotor as it revolves. This is done using the ‘Park’ transformation:

θ is the rotor angle around the static Iα and Iβ frame

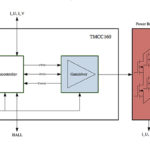

Under steady-state conditions, ID and IQ are constant values and can be interpreted as the components of stator winding current that represent tangential and unwanted radial torque, respectively. FOC uses these values as inputs to feedback loops, typically using proportional-integral (PI) controllers that work to maximize IQ and minimize ID to zero. The resulting error amplifier outputs VD and VQ are passed through inverse Park and inverse Clarke transformations with subsequent pulse width modulation to drive a power stage, generating the three sinusoidal stator winding currents. The programmable gain values in a PI controller, Kp, and Ki, must be separately optimized for transient response and steady-state accuracy, respectively, and are heavily dependent on actual motor parameters, particularly winding resistance and inductance. However, advanced FOC controllers, such as those from Qorvo [1], have auto-tuning features where they ‘learn’ the characteristics of the connected motor. An outline of a BLDC motor controller using FOC is shown in Figure 2.

Applications that benefit particularly from FOC are those where noise or vibration need to be minimized or where a low harmonic contact is desirable. In addition, FOC can enable an application to run at higher than nominal speed when required. This is achieved using ‘field weakening’ where the back-EMF is deliberately reduced by controlling the current ID to be lower to a negative value. This reduces the effective rotor magnetic field and allows higher speed, although torque is reduced.

Sensing rotor position and winding currents

The rotor angular position must be known in FOC to resolve the Id and Iq components. The stator winding currents also need to be measured.

Several methods are available to detect the rotor position. Sensorless monitoring infers the position from the winding currents, back-emf, and a model of the motor characteristics. However, starting up under high load can be difficult and may require starting the motor with a trapezoidal drive. In this case, one winding is unenergized at any instant, and the zero crossings of the back-EMF present provide an accurate indication of the position. The application can then change to sine FOC when the motor is running.

Alternatively, using Hall sensors to detect the rotor position enables starting-up under high load conditions with precise torque control. A more expensive option is to use a magnetic resolver or an encoder with quadrature outputs, which provides highly accurate position measurements and can sense the direction of rotation.

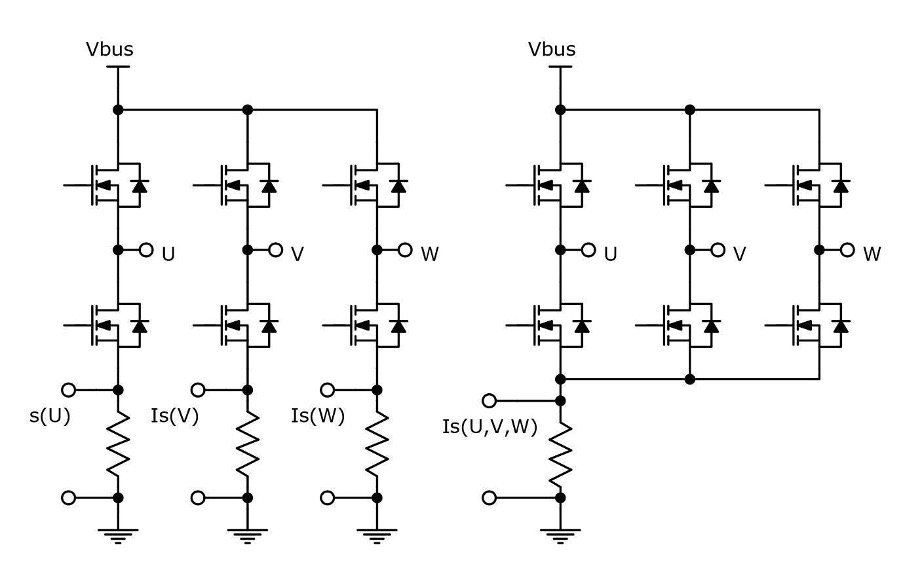

Moreover, there are different ways to measure winding current. The most accurate method is to sample each of the three winding currents simultaneously using three sensing resistors, each connected to an ADC. The usual approach is to measure the inverter leg currents (Figure 3, left).

A single shunt resistor can be used for cost-sensitive applications, effectively measuring the DC-link current (Figure 3, right). Only one ADC is needed, and the phase currents are calculated using a single-shunt current reconstruction method. The timing of current sampling is crucial to capture an accurate average value. Accuracy can be impaired by effects such as ringing if the active vector duration is less than the minimum measurement period. Asymmetrical current sampling can overcome this but requires more complex calculations.

Implementing BLDC FOC

A complete motor-control application requires power management, analog sensing, PWM generation, gate-driving functions, and the processing core responsible for executing the FOC algorithm. System-on-chip devices optimized for motor control, such as the Arm® Cortex® based PAC5xxx series from Qorvo, integrate this circuitry in a single package. One variant in this family even integrates the power MOSFETs to directly drive low-power BLDC motors for applications such as hand-held devices and tools. These Power Application Controller® ICs support the approaches discussed in this article, including sensorless rotor position measurement or detection with Hall sensors or a quadrature encoder and single-shunt or three-shunt current sensing. They also allow hybrid trapezoidal/FOC mode for assured start-up and field weakening for operation above nominal speed.

Conclusion

Understanding the differences between trapezoidal, sinusoidal, and field-oriented control and the underlying operating principles can help engineers choose the right control strategy when developing BLDC motor applications. Field-oriented control can deliver accurate speed control with fast dynamic response and minimal torque ripple and can now be implemented using a single-chip control IC.

Leave a Reply