If something can’t go on, it won’t; supplying the automobile’s voracious electrical demands from a 12-V battery is an example of this reality.

Today’s cars — whether based on the traditional internal combustion engine (ICE), some form of hybrid electric vehicle (HEV), or even a pure electric vehicle (EV) — are loaded with electronics, sensors, control units, safety features, advanced driver-assistance system (ADAS), infotainment systems, dozens of small motors, and big traction motors (for EVs/HEVs). Providing, managing, and delivering the required electrical energy/power is a major challenge. At the same time, dissipating the inevitable heat is an unavoidable consequence of this power situation.

This ever-increasing demand for more power has reached a point where it can’t continue using just the 12-V lead-acid battery. That battery can’t provide the power, and even if it could, the heavy-gauge cables needed to keep losses to an acceptable level add to the cost, weight, volume, routing issues, and assembly constraints. If you have even seen the miles of cabling and their large connectors in a modern car, much of it 12-gauge thick and inflexible, you know there’s a problem.

Change is here, with more to come

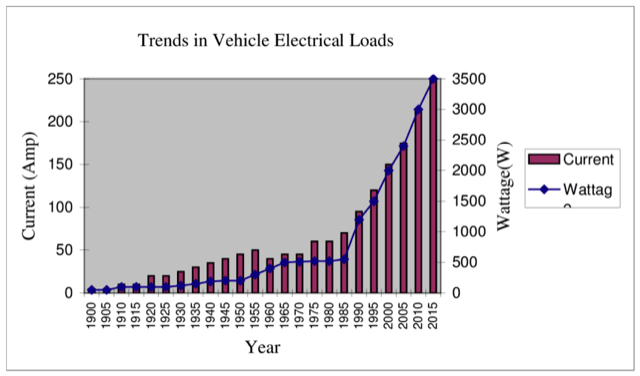

Of course, the power needs of today’s cars are several orders of magnitude greater than those of 100+ years ago. How much power does a car need (ignoring the traction motors)? One perspective shows the inexorable and dramatic rise, except for a small dip in 1970 (possibly due to the Arab oil embargo and gas shortage?); Figure 1 shows this.

A brief look at the evolution of the battery alone is illustrative. The first cars had no battery at all! The driver hand-cranked the engine to start the car to initiate rotary motion. The spark plug(s) power came from a magneto, a crude but effective enough generator attached to the engine. In effect, the cranked car created its own energy for the spark plug once it was cranked and turned over.

When the electric starter was introduced in the 1910s to 1920s, it used a 6-V battery. That battery was adequate even with the addition of the power-hungry vacuum-tube radio in the mid-1920s. Key to the ability to use a modest 6V battery for both the starter and the radio was that both were not used at the same time and that the power cable runs from the battery to the starter and radio were short and direct, thus minimizing losses.

By the early 1950s, the additional loads on the car’s electrical system increased with the addition of power options such as more lighting, air conditioning, and power steering. Many of these options were powered mechanically by belts running off the car’s engine to minimize electrical demands, with electricity used for control but not raw power.

Nonetheless, loads increased beyond what the 6-V battery could support. The industry switched to 12-V batteries to provide more available energy, reduce losses, and allow the use of thinner cables carrying higher voltages but at lower amperage (Figure 2).

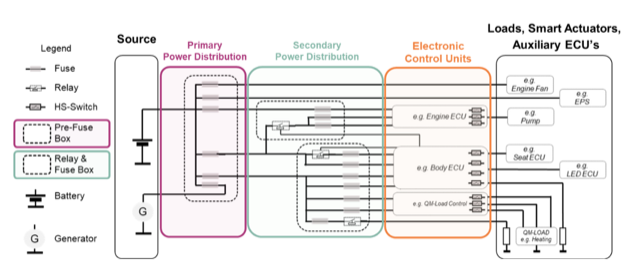

The 12-V solution lasted over 50 years, which is an impressive track record, and the interconnect diagram of the power distribution network (PDN) was simple, at least in principle (Figure 3).

However, many additional loads in the form of modern features were added. At the same time, existing functions, such as engine-driven power steering, transitioned to electric motor assist for better control. The result was a more complicated PDN (there was some initial movement towards upgrading to a 24-V battery pack in the 1990s, but that never caught on. The benefits did not outweigh the entrenched nature of the 12-V supply chain, manufacturing, and expertise) (Figure 4).

Flash forward to the 21st century, and 12 V is running out of steam, to use a mixed metaphor. When using 12 V for electronic functions, the IR drop and voltage loss is a problem. Still, it can be accommodated, to some extent, by using suitable local regulators on each circuit board. I2R Joule heating and associated power loss, however, are problems for which there is no recourse, as that power is wasted and non-recoverable, while the associated heat dissipation adds to the thermal load on the car.

The next section continues this discussion.

Related EE World content

FAQ on magnetos for power and ignition, Part 1

FAQ on magnetos for power and ignition, Part 2

FAQ on traction motors, part 1

FAQ on traction motors, part 2

FAQ on traction motors, part 3

End-to-end connector portfolio meets needs of 48-V vehicle electrical systems

Boosting performance in 48-V power distribution

Autonomous Technology’s Growing Influence On Revamping Vehicular Electric Systems

Optimizing power delivery networks

External references

Cadence Design Systems, “What Is Zonal Architecture? And Why Is it Upending the Automotive Supply Chain?”

Vicor Corp., “48V systems: What you need to know as automakers say goodbye to 12V”

Vicor Corp., “Electric Vehicles: 48V is the new 12V”

Vicor Corp., “Tesla Cybertruck will eliminate 12V electrical components”

TE Connectivity, “Connectivity in Next Generation Automotive E/E Architectures”

Infineon, “Automotive power distribution system”

Clore Automotive, “The Evolution of the Automotive Battery”

Continental Battery Systems, “Car Battery Evolution – From Old-Tech to MIXTECH”

MDPI, “Characteristics of Battery Management Systems of Electric Vehicles with Consideration of the Active and Passive Cell Balancing Process”

ResearchGate, “A Systematic Approach to the Development of the Automotive Electrical Power System Architectures”

Inside EVs, “Tesla Confirms The Switch To 48 Volt System”

Texas Instruments, “Processing the Advantages of Zone Architecture in Automotive”

Leave a Reply