Radial flux AC motors offer some performance and packaging benefits but also bring some thermal and manufacturability issues.

For many electrical and even mechanical engineers, motor selection is somewhat of a mysterious process. You can understand their basic principles and operation. Still, the real-world design considerations of their flux paths, poles, materials, and tradeoffs seems to be defined by complex yet decisive equations and electromagnetic modeling on one side, and by somewhat “magical” considerations on the other side.

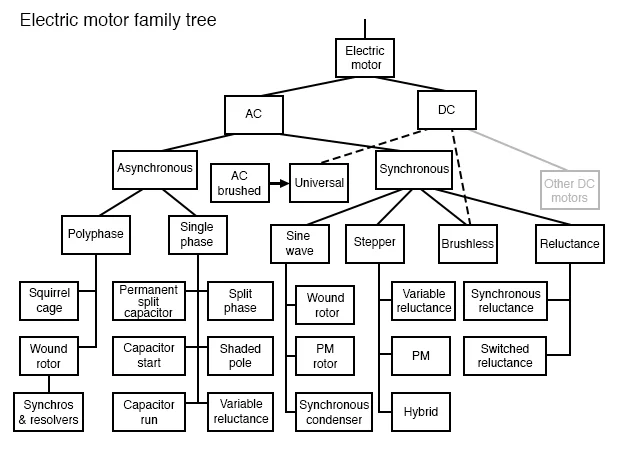

Even one perspective on the motor “family tree” is only somewhat helpful and leaves many questions unaddressed (Figure 1). Note: this image appears identically on dozens of websites and is the only halfway-decent one I have found; unfortunately, I have been unable to track it to its original source despite my considerable efforts to do so.

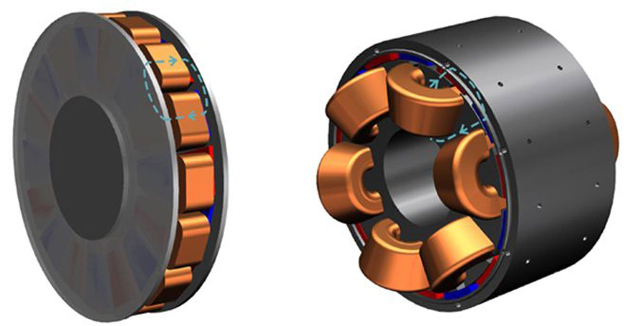

This FAQ will look in more detail at the axial-flux motor (AFM) and compare it to the very widely used radial-flux motor (RFM). The AFM is gaining traction (pun intended) in many applications, including electric vehicles (EVs). The AFM’s internal elements are arranged so that the lines of magnetic flux are in an axial direction with respect to the rotor, in contrast to the standard, very widely used radial-flux motor design.

The AFM offers some physical and performance advantages, although there are, of course, some tradeoffs. AFMs are also informally called pancake motors or disc motors. Although they are not explicitly called out on the family tree shown above, which does not call out either AFMs or RFMs, they would be under the “brushless” category.

Note: for some inexplicable reason, our acronym-happy industry rarely uses the AFM and RFM designations, preferring instead to fully spell out the three words; however, this FAQ will use the shorter and simpler acronyms rather than spell it out. Sometimes, there’s a reluctance to uses acronyms to minimize confusion with another multiword designation which has the same acronym. Still, the only other technical AFM I have found is the atomic force microscope — and there’s little chance of confusion with that.

Q: I’m a little unclear on basic motor-mechanical attributes, so can you provide a brief reminder?

A: Motors have their own unique and very necessary, lengthy set of definitions and parameters, and it would be impractical to review them all here. In addition to the obvious ones such as speed (revolutions per minute/rpm), there are these important figures of merits to keep in mind:

Torque = Force × Length of a lever arm (or “moment” arm, which is the same as the motor rotor radius).

Increasing the motor diameter increases the rotor radius and increases the motor torque even if the force generated by the magnetic fields is unchanged.

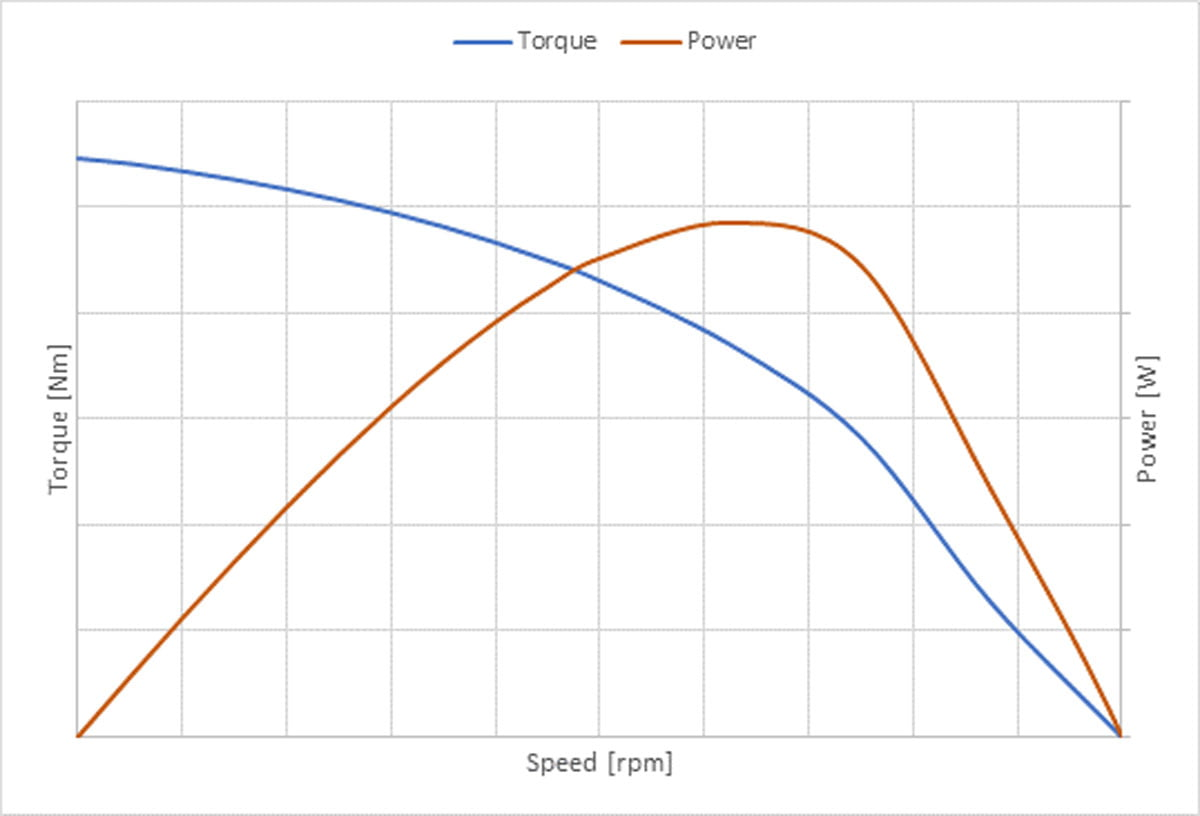

Power = Torque × Speed

Since a small motor has a short lever arm, the torque will be small, but if the motor turns at a high speed, the output power can be significant, as seen for a typical RFM or AFM (Figure 2).

Torque density: the ratio of torque capability to volume; measures the torque-carrying capability of a component in a given weight and space envelope. It is often a very critical parameter as it characterizes how useful work output can be achieved within the available package.

Finally, every motor selection has to deal with efficiency and losses. These thermal losses and material stresses in the relatively dense internal construction of wire coils, magnets, supports, and more can easily lead to overheating, insulation breakdown, deterioration of magnetics, resulting in degraded performance degradation, and even outright failure.

Q: Getting back to AFMs and RFMs, to what does “axial flux” actually refer?

A: “Axial flux” is not the name of a superhero, nor is it related to the famous “flux capacitor” used to power the DeLorean time-machine car in the classic film “Back to the Future.” Instead, it is a description of the alignment and orientation of the lines of magnetic flux in a motor.

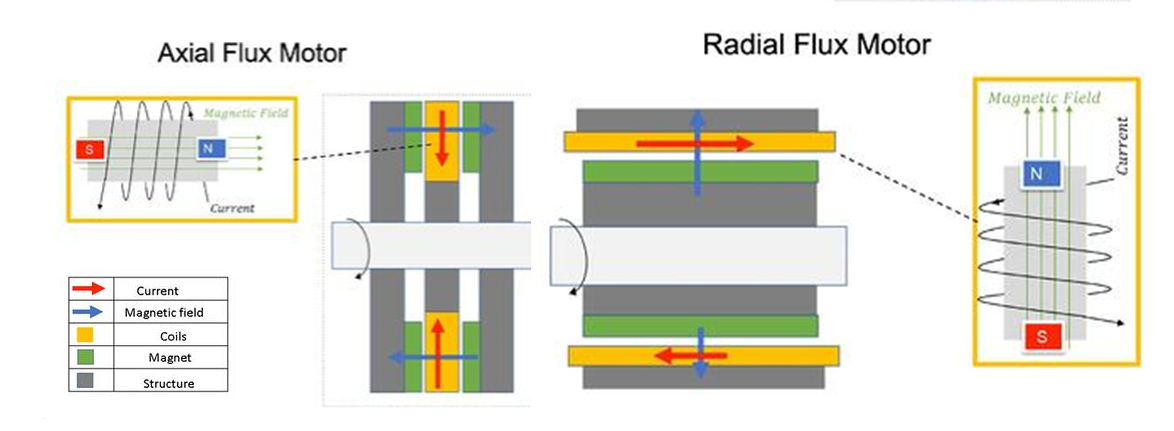

They are in the axial direction along the axis of rotation rather than emanating radially out of and back into the rotor (Figure 3). The air gap of the axial flux motor is planar, and its air gap magnetic field distribution along the axial direction, meaning that the air gap’s magnetic field is perpendicular to the air-gap plane.

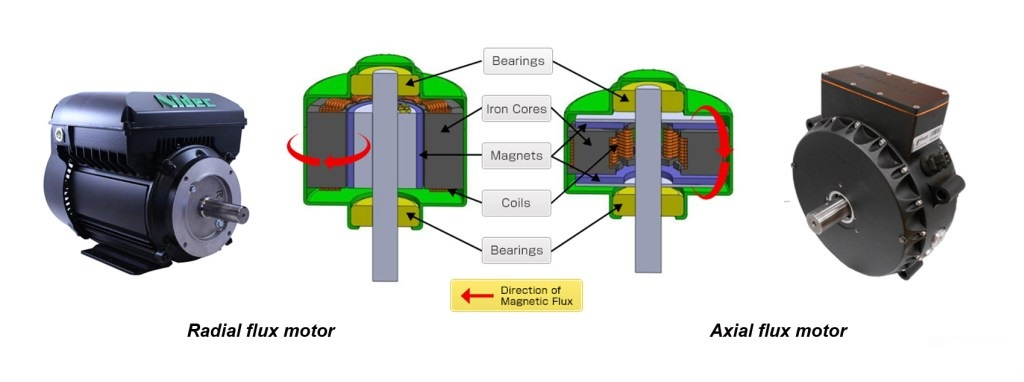

Q: I’m not really “seeing it” from that image; is there another visual representation of the flux in AFMs versus RFMs?

A: Two more visual perspectives are in Figure 4 and Figure 5.

The next part of this FAQ continued the exploration of AFMs and RFMs. The final part of this FAQ looks at some real-world issues associated with the adoption of AFMs.

EE World related content

Brushless motors and motor nameplates

Scope-based diagnosis of three-phase motor drives

Why you don’t need a variable-speed drive to change a fan’s speed

FAQ on traction motors, part 1

FAQ on traction motors, part 2

FAQ on traction motors, part 3

Unipolar vs. Bipolar drive for stepper motors, Part 1: principles

Unipolar vs. Bipolar drive for stepper motors, Part 2: Tradeoffs

Unipolar vs. Bipolar drive for stepper motors, Part 3: Drive ICs

FAQ on servo motors: part 1

FAQ on servo motors: part 2

External References

Iowa State University, “Motor Characteristics”

YASA, “Axial flux: The future of performance electric vehicle propulsion”

E-Mobility Engineering, “Axial flux motors”

Stanford Magnets, “An Overview of Axial Flux Motor & Axial Flux Motor Magnet”

Magnet Academy, National Mag Lab, “Davenport Motor – 1834”

Eaton, “Why torque density is important to machine design”

Horizon Technology, “Electric Motor Design: Radial vs. Axial & Transverse Flux”

Triaxial BV, “Axial Flux Motor vs Radial flux Motor: A Focus on Magnetic Field Orientation”

Triaxial BV, “Why Aren’t All Electric Vehicle Motors Axial Flux (Yet)?”

Magnetic Innovations, “What is a radial flux permanent magnet motor?”

Storables, “What Electric Motor Does Tesla Use?”

Tesla, “Subsystems: Motor Types and Specifications”

European Journal of Electrical Engineering, June 2014, “Magnetic Modeling of Radial-Flux and Axial-Flux Permanent-Magnet Motors for Direct Drive Automotive. Specifications and Comparison”

Oak Ridge National Laboratory, “A Comparison of Outer Rotor Radial and Axial Flux Machines for Application in Electric Vehicles”

Kilowatt Classroom LLC, “Variable Frequency Drive Fundamentals”

VFDS.org, “Variable Frequency Drives”

Leave a Reply