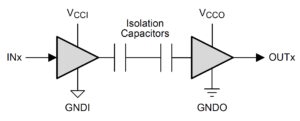

Capacitive digital isolators comprise two digital CMOS dies connected with a capacitive isolation barrier. The barrier provides galvanic isolation to meet safety regulations, reduce noise from ground loops, and connect interface communication boards or subcircuits that operate with different supply voltages. They are used in power converters and motor drives, electric vehicles (EVs), consumer devices, data acquisition and industrial automation equipment, test and measurement equipment, green energy, and medical systems.

Since they are based on capacitive coupling, these digital isolators can’t pass DC signals. Capacitive isolators are not susceptible to magnetic energy and can support high data rates with low power consumption. They can also be bidirectional. Optocouplers can also be used for isolated signal transmission but are unidirectional and have different performance characteristics.

Capacitive digital isolators use silicon dioxide (SiO2)- based high-voltage capacitors to provide the isolation barrier (Figure 1). SiO2 has a higher dielectric strength than can be delivered by an optocoupler. In addition, SiO2 can withstand extended exposure to ambient moisture, operates well at elevated temperatures, and produces an isolation barrier with a life expectancy of over 50 years.

CMOS-based digital isolators are available with isolation ratings of 5 kV, provide compliance to compliance to IEC 60747-5-2, and include 10 kV surge protection as required by IEC 60065. Furthermore, they comply with IEC 60950-1, 61010-1, and 60601-1 (reinforced insulation) with working voltages up to 1200 V. Many digital isolators are rated for -40 to +125 °C operating temperatures.

Digital isolators vs optocouplers

Optocouplers have been successfully used for many years. However, many emerging Industry 4.0 and green energy systems require performance and reliability that can’t be delivered using an optocoupler. The LED in an optocoupler is subject to aging and wear-out after about ten years while emerging applications often require 20+ year warranties. For example, PV panels are typically rated for 20 years of operation and require inverters and other system elements that deliver the same lifetime. That requires the use of digital isolators.

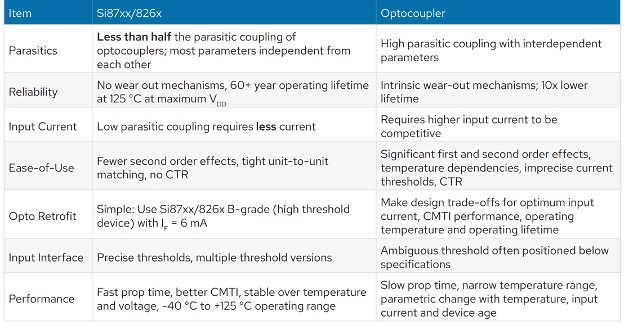

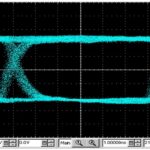

Compared with optocouplers, digital isolators have faster propagation times and higher common-mode transient immunity (CMTI), making them more suitable for electrically noisy environments. Parasitic coupling in digital isolators is under half the amount in optocouplers, making most of the operating parameters independent of each other. On the other hand, optocoupler parameters exhibit a high degree of interdependence, reducing the robustness of the operation. Table 1 summarizes some of the performance differences between digital isolators and optocouplers.

Optocoupler replacements

The inherent performance limitations of optocouplers and the growing interest in digital isolators have resulted in the development of digital isolators that are drop-in replacements for some popular optocouplers. These isolators are package and pin-compatible with one-channel optocouplers and have data rates up to 15 Mbps. They enable the replacement of optocouplers in existing designs without changes to the PCB.

Replacing an optocoupler with a capacitive digital isolator results in lower power consumption, longer operating lifetimes, improved temperature performance, and high data rates. Some of the performance advantages of digital isolators include:

- Inherently resistant to temperature, aging, and forward current effects

- 10x lower failures in time (FIT) rate produces longer service life

- Higher common-mode transient immunity of over 50 kV/µs

- Lower power consumption and cooler operation

Summary

Capacitive digital isolators based on SiO2 high-voltage capacitor technology are increasingly replacing optocouplers in a wide range of applications. In some cases, the lower power consumption of the digital isolators is the deciding factor; in other cases, their superior performance and longer lifetimes are the critical differences. Capacitive digital isolators have been developed as drop-in replacements for optocouplers.

References

Anatomy of a Digital Isolator, Analog Devices

Capacitive Isolation: A Fundamental Building Block in Future AC/DC Power Conversion, Monolithic Power Systems

Considerations for Selecting Digital Isolators, Texas Instruments

Digital Isolator Evolution Drives Optocoupler Replacement, Skyworks

Leave a Reply