The types of electric motors and drives depend on the style of the oven. Deck ovens usually don’t have any motor. Rotating and conveyor ovens are available with a variety of motor types, and each type of motor uses a specific drive technology.

This article looks at some typical uses for brushed direct current (BDC), brushless DC (BLDC) motors, and alternating current (AC) motors in pizza ovens.

Different motor technologies have different performance and cost tradeoffs and are used in different applications. BDC, BLDC, and AC motors can all be used for various conveyor designs. BLDC and AC motors compress air in hot-air-impingement ovens, and AC motors are found in rotating ovens.

Brushed DC motors

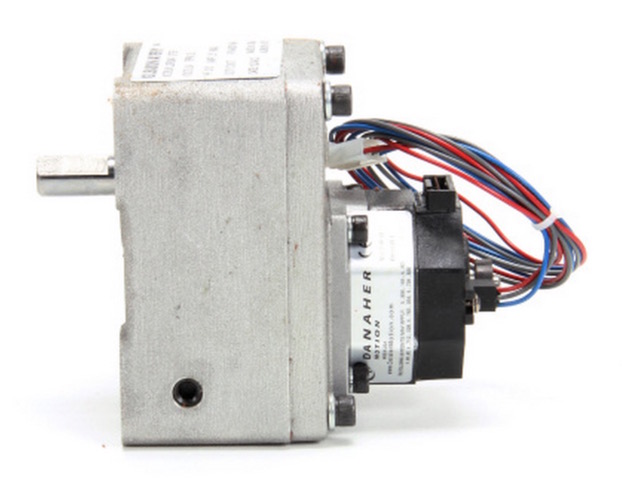

Brushed DC (BDC) motors in pizza ovens are most often used for moving pizzas on a conveyor. BDC motors have rotating coils in their center surrounded by stationary permanent magnets.

Key components in a BDC are the commutator and brushes. The commutator is a cylinder with multiple metal contact segments on the rotating armature coil in the center of the motor. The brushes make sliding electrical contact with the commutator as it rotates, connecting the coil in the center to the power source on the outside of the motor.

A BDC’s speed and torque are proportional to the applied voltage and current. This makes BDCs simple to control and minimizes the cost of variable-speed conveyor systems.

Due to friction between the commutator and brushes, BDC motors’ efficiency is typically only 75-80%, less than that of other motors used to power pizza oven conveyors. BDCs also have higher maintenance needs since the brushes are subject to physical wear and need to be periodically replaced. They can also require cleaning to prevent unplanned downtime.

Digital speed controllers are available for BDC motors. Some designs include dip switches to set up the controller for specific ovens, and they can be manually adjusted when needed. They include a soft start function to reduce conveyor wear and jamming and protection from bad sensors, bad motors, and other anomalous operating conditions.

BLDC motors

The mechanical commutator and brushes in a BDC motor are replaced by electronics in a BLDC motor, that’s why they are also called electronically commutated (EC) motors. Replacing the mechanical parts with electronics produces more precise and repeatable position and speed control for pizza oven conveyors.

BLDCs are also more efficient than BDC motors. Removing the commutator and brushes reduces friction, boosting efficiencies up to 90%. The newest BLDCs used in pizza ovens are stepper motors that rotate in a series of small angular steps instead of continuously. That provides a greater degree of control over conveyor movement.

While BDC motors are mostly relegated for use in conveyors, BLDC motors are also used to drive compressed air in hot-air-impingement ovens. In hot-air-impingement, air is blown through nozzles onto the pizza at a pressure of about 0.6 pounds per square inch (psi). BLDC motors can produce significantly smaller hot air compression systems compared with AC motors.

AC motors

AC motors, also called AC induction motors, are used in all pizza oven applications, including conveyors, compressing hot air, and rotating ovens. BDC and BLDC motors are not found in rotating ovens.

AC motors are simple machines that don’t have mechanical brushes and don’t need an electronic drive. Depending on the design, AC induction motors can deliver efficiencies comparable to BLDC motors. Typical AC motors used in pizza ovens range from 1/3 to 3/4 horsepower (HP) and are designed to operate from single-phase 120 Vac.

Common AC induction motors used in pizza ovens operate at 1,800 revolutions per minute (rpm) and are connected to the conveyor with a gearbox to reduce the speed. An electronic controller can be added for increased functionality.

Another important specification of AC motors is the service factor (SF). SF is the percentage of overloading that the motor can handle for short periods of time when operating within its specified voltage rating. A motor with an SF of 1.15 indicates that the motor can produce 15% more power when overloaded for a short time. Typical SF ratings for pizza oven AC motors range from 1.0 to 1.35.

Summary

Several electric motor technologies, including BDC, BLDC, and AC, are used in pizza ovens. These technologies provide oven designers with tradeoffs in terms of cost, performance, efficiency, operating lifetime, and system size. The newest motor technology found in these ovens is BLDC stepper motors, which provide the most control over conveyor movement and the smallest size of hot air compressors.

References

Hot air for quick cooking, ebm papst

Pizza Oven Motors, Electric Motor Warehouse

Types Of Motors Used In Commercial Restaurant Equipment, PartsFe

Real pizza ovens don’t have motors. They don’t rotate and they don’t have conveyers. Pizza goes in and out by hand.