PREMO releases the new 11kW 3DPower solution, a Full Bridge LLC Transformer 150 µH + Resonant Choke 25 µH merged in 1 single unit. This innovation provides up to 40-50% reduction in volume compared with current discrete industrial solutions for the same power management.

PREMO releases the new 11kW 3DPower solution, a Full Bridge LLC Transformer 150 µH + Resonant Choke 25 µH merged in 1 single unit. This innovation provides up to 40-50% reduction in volume compared with current discrete industrial solutions for the same power management.

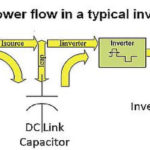

Most of the Power Converters (resonant topologies) in the market have a Transformer, Resonant Choke, and Output choke. Every component has its own design, core, winding, and thermal dissipation solution.

3DPower is the first product to integrate two magnetics components that share the same core and feature two orthogonal magnetic fields at all points within the core. A unique and single solution that gives a super advantage starting at the beginning of the value chain includes a Power converter design with one inductive component in mind; One mechanical drawing interface to fit and connect; Improvement of MTBF; Important volume and weight reduction (-40 to -50%); Energy efficiency & cost effective; Carbon footprint reduction worldwide (energy reduction to produce magnetic cores). X3 Reduction of Ferrites;

Once the electromagnetic performance is reached, internal and external thermal links are the most important question to solve in the design of these 3D-Power components: “Heat Dissipation”. Designing power densities and power sizes over 7kW turns in a heat increase. 3Dpower use CoolMag, a full silicon compound compatible with the magnetics 100% focused on power magnetic electronics to dissipate the heat from the top of the magnetic to the liquid cooling plate of the bottom is required. It provides a thermal conductivity bigger than 1.7 watts/mK. The air is removed by this silicon to improve heat dissipation.

The 3DP-11KWHVHV is available with an Aluminum heatsink that acts as a direct thermal interface to the cold plate. 3DPower cost-saving solution is also available with 7kW and the company is developing the 22kW solution. Designs can be fully customized according to customer requirements.

The 3DPower 3DP-11KWHVHV Series meets the AEC-Q200 (specific automotive quality standard) and other more restrictive customer automotive supplier standards. This greener solution has been fully tested in Premo Laboratory under real operational conditions.

Leave a Reply