A few basic parameters can be useful for selecting power supplies that must work dependably in specific application scenarios.

Alex Karapetian Acopian Power Supplies

Electronic devices require a reliable source that can supply power at all times. But power supplies are available in a wide range of voltage and current ratings. Engineers tasked with selecting an appropriate power supply must resolve numerous questions to determine which supply suits an application. A good place to start with this analysis is to look at two main power supply design topologies: switching and linear regulated.

Switching supplies can either step-up or step-down the input voltage to get the desired output voltage. Applications where a switching power supply may be preferable include those where small size, low weight, and high energy efficiency are important. They include high power/high current uses, portable equipment, control systems, dc motors, aviation and marine applications, network equipment, electrolysis and waste treatment operations.

Linear power supplies typically step-down an input voltage to produce a lower output voltage. Though it is larger, heavier, and not as efficient as a comparable switching supply, the linear unit has beneficial attributes that the switcher supply cannot match. For example, the linear supply has no discrete time clocking or switching action. Consequently, the output is virtually noise and ripple free. Typical applications of linear regulated power supplies include telecommunications equipment, medical equipment, laboratory test equipment, low-noise amplifiers, advanced signal processing and data acquisition systems (sensors, multiplexers, A/D converters and sample and hold circuits), and precision measurement devices.

Failure proof

Systems where reliability is essential and a sudden loss of power would lead to disaster need two bulletproof power sources.

Redundant power entails more than simply paralleling the outputs of multiple power supplies. (In general, power supplies may not be built to work in parallel with other supplies. Simple parallel power connections can sometimes damage the paralleled supplies.) Instead, redundant power packages contain two identical power supplies with their outputs interconnected through a diode switching arrangement. The switching arrangement will detect any fault condition, isolate it from the system output, and pass only the output of the good supply with no interruption of output power during the transition. Redundant power systems come with various features including over- and undervoltage, surge protection, isolation diodes, alarms and remote voltage sensing.

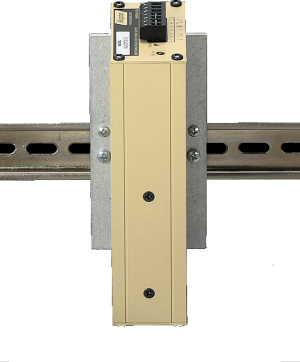

Many power supply manufacturers provide simple DIN rail mounting kits for many of their power supplies. For instance the EB35DIN mounting kit from Acopian includes an aluminum plate with two DIN clips attached to it. Four screws attach the plate to the bottom of any mini-encapsulated power supply or mini dc-dc converter with screw terminals. The power supply can then be snapped onto a 35-mm ‘top hat’ type DIN rail.

Low noise supplies

Electrical devices switching on and off create electrical noise having a spectrum consisting of a fundamental at the switching frequency as well as numerous harmonics. Another source of conducted electromagnetic interference (EMI) is ripple in the converter output. Ripple can be a factor because rectification and filtering of a switching supply’s output causes an ac component that rides the dc output. Typical ripple noise levels are on the order of hundreds of microvolts to tens of millivolts. This level is unacceptable in medical equipment, low-noise amplifiers, signal processing, data acquisition, automatic test equipment and laboratory test equipment.

Linear regulated power supplies have little ripple and little output noise, making them suitable for laboratory, medical and instrumentation applications. Equipment that generates and manages X-ray data, requiring reliable, consistent and clean power is an example. In one case, a linear power supply handled a dark room environment for developing X-ray imagery. All LED indicators and digital meters on the supply could be switched off while the power system was in use; toggle switches on the front panel provided individual control of LED indicators and digital meter backlighting.

For the defense industry, components must withstand the extreme environmental conditions that the military faces. In particular, power supply systems must be designed and qualified to strict manufacturing, environmental and operational Military Specifications (MIL-SPEC).

MIL-STD-704 (Aircraft Electrical Power Characteristics) for instance, is a U.S. military standard that defines a standard power interface between a military aircraft and its equipment and carriage stores. The standard covers such topics as voltage, frequency, phase, power factor, ripple, maximum current, electrical noise and abnormal conditions for both ac and dc systems. A point to note is the requirements and specifications for defense applications are unique. Such requirements may prevent standard switching power supplies from meeting military design needs.

Online tools that power supply manufacturers provide can speed the supply selection process. An example is the online Acopian custom system builder. Engineers can use this tool to easily custom-design dc-dc and ac-dc power supplies with just a few clicks, selecting options that range from the number of outputs to the topology of the supply circuit.

Leave a Reply