There are multiple types of magnets, including temporary magnets, permanent magnets, and electromagnets. Each type of magnet has a variety of uses and can contribute to a more sustainable society.

This FAQ reviews the basics of each type of magnet, looks at what it can be used for, presents some efforts to develop sustainable permanent magnets, and closes by looking at how electropermanent magnets combine hard and soft magnetic materials to improve sustainability in specific industrial applications.

Within each of the three primary magnet-type classifications are multiple subcategories (Figure 1). In the case of permanent magnets and electromagnets, those subcategories include materials and designs optimized for specific characteristics as well as improving sustainability.

Temporary magnets

Temporary magnets are magnetic only in the presence of an external magnetic field. Materials like iron, nickel, cobalt, and many types of steel can act as temporary magnets. The field strength of temporary magnets is related to the material being used and the external magnetic field’s strength, proximity, and other characteristics. As soon as the external field is removed, temporary magnets stop being magnetic. Characteristics of temporary magnets include:

- Easily magnetized by an external magnetic field

- Simple structures

- Low cost

- Can be used to set canate metals and nonmetals

Most nonmetal magnetic materials are temperature sensitive, and the strength of their magnetic field decreases at elevated temperatures. In addition, many of these materials have low corrosion resistance.

Paramagnetic and superparamagnetic temporary magnets

While temporary magnets are often associated with ferrous materials, paramagnetic and superparamagnetic materials can also be used for temporary magnets. Paramagnetic materials like alkali metals, some transition metals, aluminum, tin, and oxygen, have a weaker field strength compared with ferrous materials.

Superparamagnetism is paramagnetism at a very strong level, and superparamagnetic temporary magnets can be very strong, but there’s a catch. Superparamagnetism is highly size-dependent and only exists in nanocrystals. It’s a form of magnetism that appears in small ferromagnetic or ferrimagnetic nanoparticles. Like the case of a paramagnetic material, an external magnetic field can magnetize the nanoparticles in a superparamagnetic material. Still, the magnetic susceptibility, the degree of magnetization in an external magnetic field, is much larger than that of regular paramagnets.

Permanent magnets

Unlike temporary magnets that need the application of an external field to become magnetized, permanent magnetics generate their own field. Permanent magnets can retain their magnetic properties for extended periods, even multiple years. Permanent magnets can also provide the magnetic field to use temporary magnetic materials.

Permanent magnets are often divided into two groups, metal alloy magnets like aluminum nickel cobalt magnets, samarium cobalt magnets, neodymium iron boron magnets, and ferrite or ceramic magnets.

Ceramic or ferrite magnetic materials can be soft (easily magnetized and unmagnetized) or hard (difficult to magnetize and unmagnetized). Ceramic or ferrite permanent magnets are made with hard magnetic materials like barium hexaferrite (BaFe12O19) and strontium hexaferrite (SrFe12O19). Both materials are hard and brittle and represent the largest permanent magnets used today. They generate moderate remanence induction but have performance advantages in terms of resistance to demagnetization and corrosion and the absence of eddy current losses. They have good availability and are low cost. If the performance of these materials could be increased even modestly, they could take away market share from higher-performing metal alloy magnets.

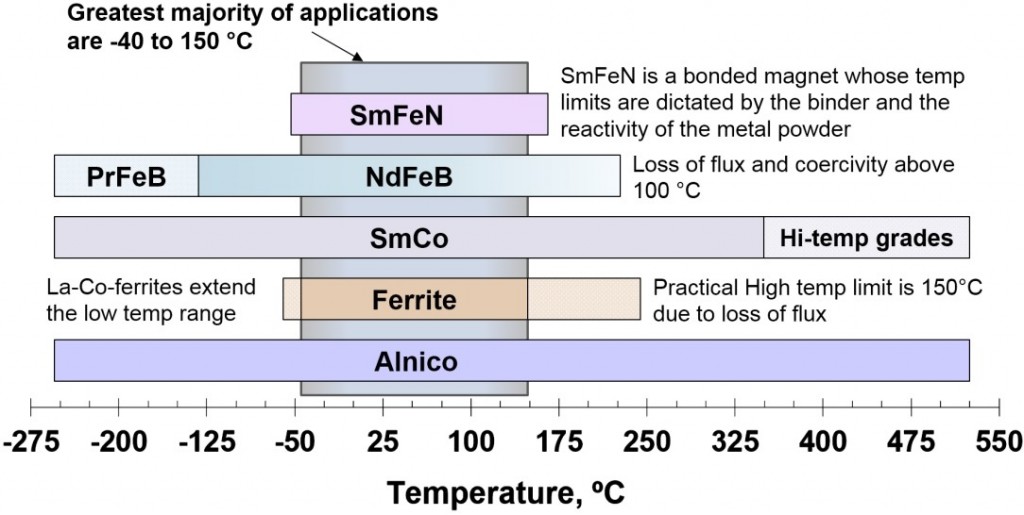

Permanent magnets made with aluminum, nickel, and cobalt are called alnico magnets. They have good temperature performance but are relatively easy to demagnetize. Their overall performance and cost places them between ceramic or ferrite magnets and rare earth magnets. Alnico magnets can be fabricated using sintering or casting processes. Sintering results in mechanically more robust magnets, while casting produces higher magnetic energy levels and can support the production of magnets with more complex shapes.

Samarium Cobalt (SmCo) magnets are rare earth magnets and can be made with Sm1Co5 and Sm2Co17, referred to as 1:5 and 2:17, respectively. Magnets made with 1:5 have an energy range of about 15-20 mega-gauss-Oersted (MGOe), and 2:17 magnets have an energy range of about 22-30 MGOe. SmCo magnets are not easily demagnetized. They have low mechanical strength and are expensive but can operate up to 350 °C, higher than most other types of permanent magnets. They are best suited for extremely high-temperature environments like downhole oil and gas exploration.

Neodymium Iron Boron (NdFeB) magnets are also rare earth magnets. NdFeB magnets feature very high energy products, up to 45 MGOe, and have extremely high coercive forces. These magnets can be used up to about 200 °C, and their high energy products enable the use of smaller magnets to achieve the same energy product. However, NdFeB magnets have low mechanical strength and are very brittle. They find use in high-performance applications like motive motors in electric vehicles.

Samarium iron-nickel (SmFeN) magnets are still mostly under development. They have a saturation magnetization strength comparable to NdFeB but can operate over 400 °C. They have superior oxidation and corrosion resistance and do not need to use cobalt or other heavy rare earth elements, potentially giving them superior sustainability performance.

Most applications have operating temperature ranges that fit between -40 and 150°C. All the common permanent magnet materials discussed above can operate over that temperature range (Figure 2).

Sustainable permanent magnets

Using rare earths to fabricate high-performance permanent magnets is fraught with sustainability challenges. Most notably, the mining and processing of rare earths produces toxic by-products, leading to ecological and sustainability challenges with rare-earth mines and refineries. Demand for high-performance magnets with improves sustainability is driving numerous research efforts.

For example, scientists at the University of Leeds are developing a hybrid film from a thin layer of cobalt (which is ferromagnetic) covered with Buckminsterfullerene, a form of carbon. While carbon is not magnetic, when bonded to the cobalt surface, the carbon causes a magnetic pinning effect, preventing the magnetism in the cobalt from changing directions, even in the presence of strong opposing fields. The carbon layer boosts the energy product of the resulting structure by 5x at low temperatures. The next step in the research aims to increase the operating temperature of these magnets to room temperature.

In another instance, a team at the Critical Materials Institute at Ames Laboratory has identified two forms of cerium cobalt, CeCo3, and CeCo5, as potential materials for making strong permanent magnets. Although cerium is a rare-earth element, it is abundant and easy to obtain without detrimental environmental impact and with good sustainability. While CeCo3 is a paramagnetic material, adding magnesium transforms it into a ferromagnet. CeCo5 is natively a strong ferromagnet. Adding copper and iron to CeCo3 and CeCo5 can increase the materials’ ferromagnetic capabilities and potentially make them candidates to replace NdFeB rare earth permanent magnets.

Electromagnets

Electromagnets are made with a coil of insulated copper wire, a ferromagnetic or ferrimagnetic material core, and an AC or DC power supply. Current flowing through the wire coil creates a magnetic field. The magnetic core concentrates the magnetic flux and makes a more powerful magnet.

Electromagnets are often used in place of permanent magnets. The strength of the magnetic field can be increased or decreased by increasing or decreasing the current flow in the coil, while the magnetic fields of permanent magnets are fixed. The magnetic field can be reversed by reversing the current flow direction. In addition, an electromagnet can be turned completely off with no remaining field. Disadvantages of electromagnets include the need for a continuous supply of power and their tendency to get hot when current flows are high. Combining an electromagnetic section with permanent magnets can result in improved sustainability.

Electro permanent magnets for sustainability

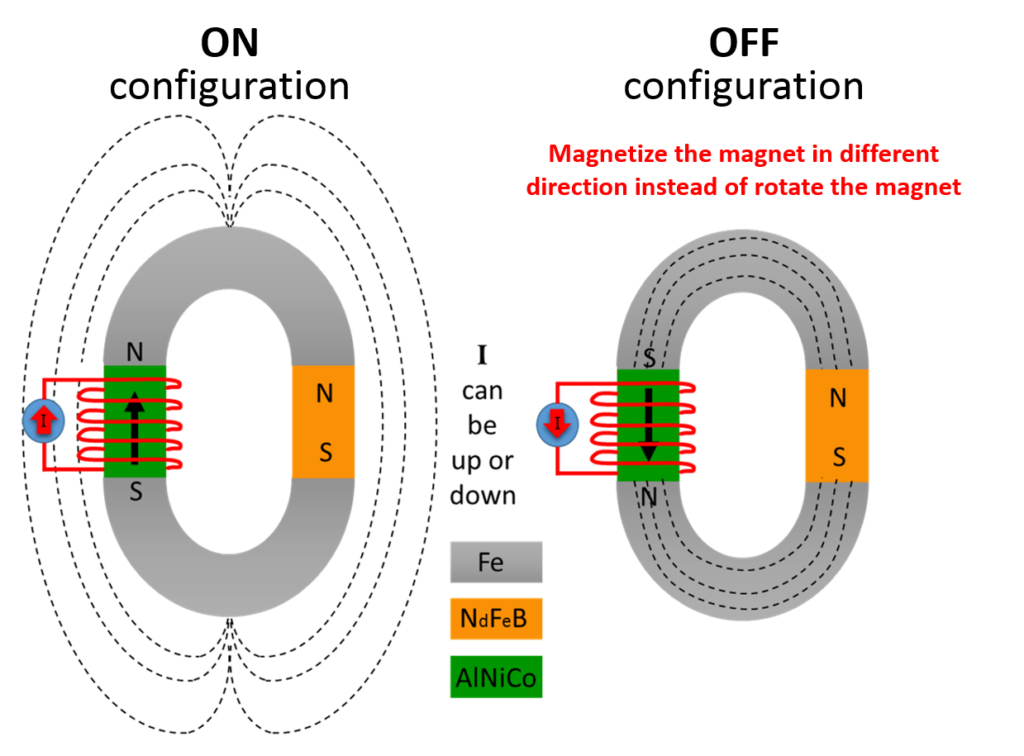

An electropermanent magnet (EPM) consists of two sections, a very hard, high coercivity (H), magnetic material like neodymium-iron-boron (NdFeB) with an H of about 1120kA/m and a lower coercivity material like alnico (AlNiCo) with an H of about 50kA/m connected with two iron horseshoes. The direction of magnetization in the soft material can be changed by a current flowing in a winding. When the two types of magnetic materials have opposing magnetizations, the EPM produces no net external field across its poles. The field is restricted to the interior of the iron horseshoes. When the magnetizations in the two materials are aligned, the EPM can produce a strong external field. (Figure 3).

EPMs can be a form of a programmable or controllable magnet. A common use of EPMs is in industrial holding magnets. When the magnetic circuit is OFF, it allows for less current (no power flow) and safe holding of magnetic workpieces. When the coil is turned on, the permanent magnetic field is canceled at the holding surface, and the workpiece can be easily removed. These controllable magnetic systems are very energy efficient and sustainable. The current flows only briefly to allow the removal of the workpiece. At all other times, there is no current flow. This design is especially efficient for applications that require long holding times or when loads or workpieces must be safely held, even during a power failure.

EPMs are commonly used for highly energy-efficient industrial lifting of ferrous metal objects. Before EPMs were developed, the only way to produce a programmable or controllable magnetic field needed to use electromagnets that consume large amounts of power when in operation. The development of powerful NdFeB rare earth permanent magnets made EPMs possible. Researchers are also investigating the possibility of enabling self-building structures using EPMs.

Summary

The primary types of magnets include temporary magnets, permanent magnets, and electromagnets. Especially for permanent magnets using rate earths, efforts are underway to develop new formulations that can improve sustainability while maintaining magnetic performance characteristics. In addition, EPM have been developed to improve the performance and sustainability of electromagnets.

References

3 Key parameters to Consider when Choosing a Permanent Magnet, Arnold Magnetic Technologies

Atomic Cooperation in Enhancing Magnetism: (Fe, Cu)- doped CeCo5, ScienceDirect

Electromagnet, Wikipedia

Electropermanent magnet, Wikipedia

Hope for a new permanent magnet that’s cheap and sustainable, Science Daily

Permanentmagnetic electro holding magnets, Kendrion

Types of Magnets, Javatpoint

I like that you mentioned how there are multiple types of magnets, including temporary magnets, permanent magnets, and electromagnets. I was watching a video last night and it showed how magnets work. From what I’ve seen, it seems there are rare earth pot magnets now too.