Doing something the same way as in the past rarely produces improved results. Technology is constantly evolving and improving, and new technologies can require new approaches. In the case of the power electronic systems discussed below, artificial intelligence (AI) and machine learning (ML) are common themes in these advanced control strategies and system architectures. Another development is the use of the Internet to offload computationally intense activities like ML functions to reduce system costs. All these developments lead to performance and efficiency improvements and contribute to sustainability.

This FAQ reviews developments that can produce step function improvements in performance. It begins with a look at multiplexing uninterruptible power supplies (UPS), considers the benefits of using deep reinforcement learning (DRL) with distributed renewable energy generation, reviews several control strategies for voltage source converters (VSCs) in distributed generation (DG) and microgrid systems and closes by presenting the possibility of using distributed power factor correction (PFC).

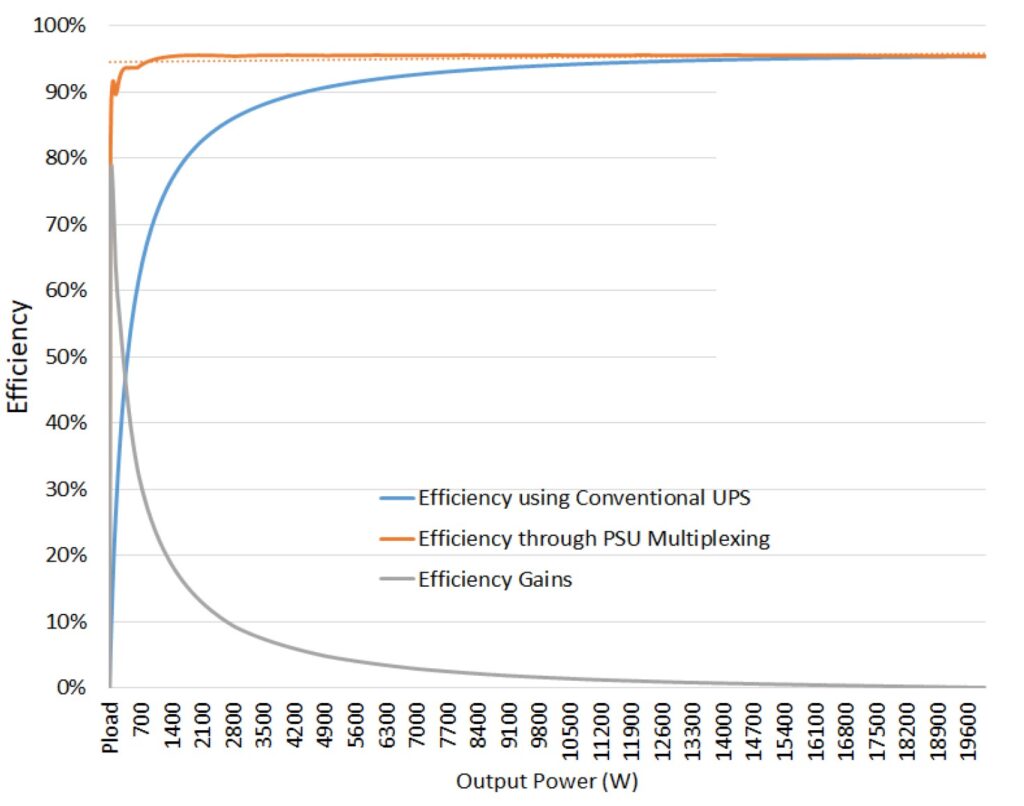

Power converter efficiency is affected by the loading factor. Light loading generally leads to lower efficiency. In applications like UPSs in a data center, loading conditions can vary widely. In addition, there’s a desire for redundant operation. Various redundant configurations have different loading factors. For N+N redundancy, the loading factor is about 50% or lower. For N+1 redundancy, the loading factor can be higher but will also be quite variable in most installations.

To address the challenges of variable UPS loading, power supply unit multiplexing (PSUM) has been designed to improve loading factors and control redundancy levels like N+0, N+1, or N+N. While developed specifically for use with UPSs, the same concept is expected to be usable in any power conversion system with variable loading including industrial installations and electric vehicle infrastructure.

Of course, loading is only one factor. Input voltages and other factors can also affect efficiency. And different UPS implementations can offer different efficiencies. In a system consisting of several UPSs that vary in size and other factors, the PSUM is designed to turn on and off various combinations of UPSs to achieve optimal efficiency based on real-time loading conditions and to support the required level of redundancy, which can also be a variable in the system. The control is based on the measured efficiency values for the individual UPSs combined with machine learning to identify the optimal combination of UPSs for maximum efficiency and the required redundancy (Figure 1).

DRL for volt/var control

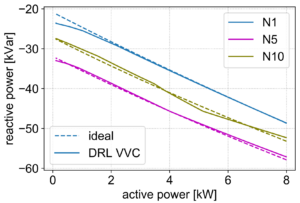

Power grid operators are being challenged by the increasing use of distributed renewable energy generation from wind farms and photovoltaic installations that can result in significant fluctuations in the grid voltage. Those fluctuations are often dealt with using reactive power, volt-amperes reactive (var), to ensure grid integrity. However, it’s difficult to use a centralized control process to arrive at the correct volt-var balance in real time and effectively deal with distributed renewable generation sources. Deep reinforcement learning (DRL) may provide a solution.

DRL is already being used in robotics and other applications. It’s being applied to power grids to control the operation of dispersed and networked voltage regulation devices. DRL algorithms combined with a deep deterministic policy gradient (DDPG) agent are being explored for use in volt-var control (VVC) using smart inverters. DDPG is a reinforcement learning agent that searches for an optimal policy that maximizes the expected cumulative long-term reward.

The test simulation included a variable PV energy source. The control algorithm continually adapts to short-term fluctuations in power flow and to changing grid connections over the long term without needing any network connection. The system required real-time independent control of reactive power from -20 to -60 kvar at several power nodes to maintain a level grid voltage (Figure 2). For purposes of the study, a tight voltage tolerance was imposed. In a real-world grid, a wider voltage tolerance can be used meaning less reactive power would be needed and making it easier to implement DRL VVC.

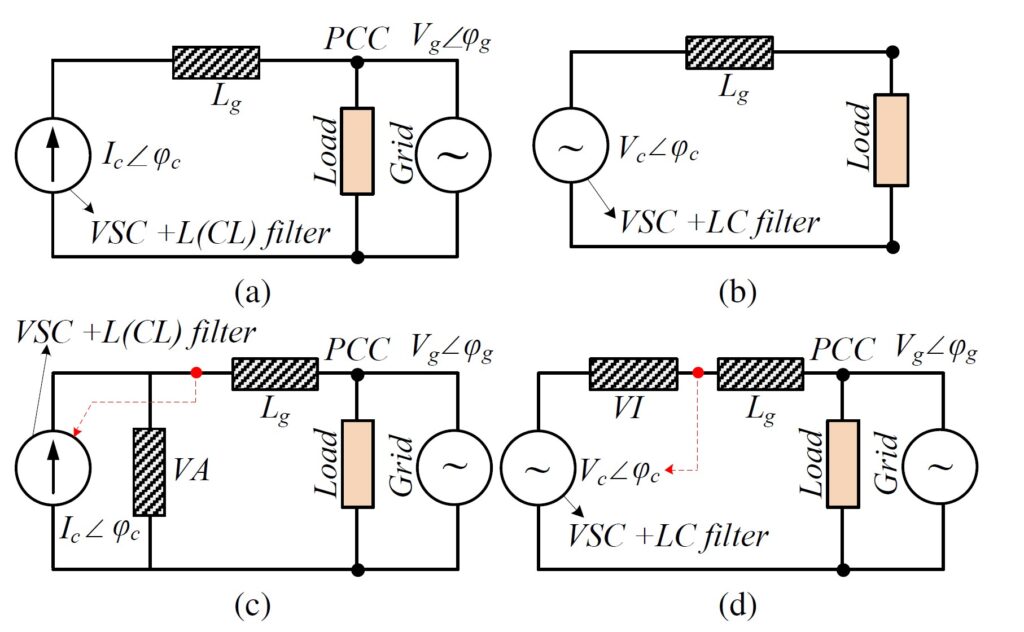

VSCs and microgrids

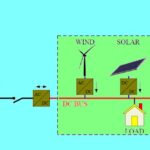

VSCs are used in EVs, microgrids, and similar applications. VSCs are used for three primary purposes in distributed generation and microgrids: grid forming, grid feeding, and grid supporting (Figure 3). Grid-forming inverters use a rigid voltage control, grid-feeding inverters use a rigid current or power control, and grid-supporting inverters use a flexible combination of voltage, current, and/or power control depending on microgrid conditions. In addition, grid-forming inverters define the grid and therefore don’t require grid synchronization, while grid-supporting and grid-feeding inverters require synchronization.

Control schemes for VSCs in DG systems and microgrids are divided into inner and outer control loops. Inner loops control the operation in the VSC while outer control loops control the interaction of the VSC with the grid. Advanced control schemes can be further divided into model- and data-based techniques. Model-based control techniques use a mathematical model of the VSC to derive the control signal. Examples of advanced model-based control include:

- State Feedback Control (SFC) focuses on the design of multiple input, multiple output (MIMO) control structures using multi-variable state-feedback controllers to achieve predefined performance measures and is implemented using a modulator structure.

- Sliding Mode Control (SMC) uses sliding surface functions based on linear combinations of various signals like the current error and its derivative, the output capacitor filter voltage error and its derivative, and derivatives and integrals of estimated currents and voltages. SMC uses a discontinuous feedback control that forces the system to equilibrium in a short amount of time based on a MIMO control structure.

- Model Predictive Control (MPC) is an optimization strategy based on a predictive control model, a cost function, and an optimization algorithm. The cost function compares predicted state variables with reference values. MPC also allows the definition of a MIMO control structure to merge multiple control loops in a single stage. The lack of applicable stability analysis methods, however, has limited the use of MPC.

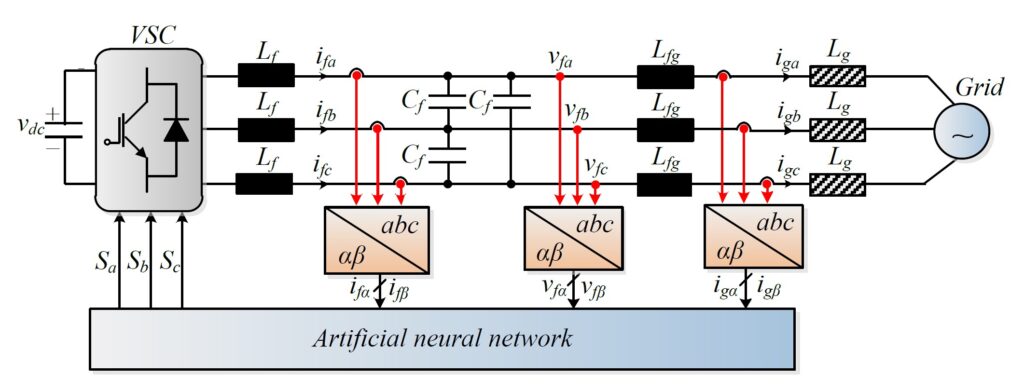

Data-based control uses the available input/output data to describe the controlled system. Data can be derived from the real system or from a model.

Artificial Neural Network (ANN) control implements non-parametric function approximations using basic algebraic operations. ANNs can be trained to estimate any given nonlinear relationship between input and output data with a desired level of precision and can be implemented as a direct or indirect control. ANNs can replace individual linear controllers in a cascaded structure or be implemented as a MIMO controller. ANNs can be used to implement finite control set (FCS) MPC control with very light computational needs (Figure 4). But they suffer from practical drawbacks like regular MCP implementations.

Fuzzy Control uses function approximation rules to transform sets of inputs like the error between a reference value and measured signal into one or more control outputs or feedback signals. Fuzzy controllers have been developed to replace the current controller in a gird feeding VSC. They can also be used to implement a MIMO control structure.

Distributed PFC

PFC is generally implemented as a centralized function within a power converter or on a utility grid. A new approach to PFC has been developed based on remote configuration supported by real-time telemetry. This technique provides enhanced flexibility and adaptability and can be used to change grid-connected capacitance values in real-time as required to maintain the needed power factor.

While it can be important to provide real-time PFC support, it’s not usually a critical function demanding fast control loops. That means that the control algorithm can be remotely located and connected to the PFC equipment through the internet, reducing the requirements for local computing power. And this approach lends itself to using a real-time feedback loop and AI for continuous improvements in PFC system performance.

Summary

Advanced control techniques are being developed for a range of power conversion, green energy, and power quality applications. In several cases, AI and ML are being used to improve performance, and the internet is being used to offload computational complex operations, enhancing system flexibility while also reducing system complexity and cost.

References

A Novel Machine Learning-Based Load-Adaptive Power Supply System for Improved Energy Efficiency in Datacenters, IEEE Access

Adaptive Online-Learning Volt-Var Control for Smart Inverters Using Deep Reinforcement Learning, MDPI energies

Advanced Control Methods for Power Converters in DG Systems and Microgrids, IEEE Transactions on Industrial Electronics

Artificial Neural Network-Based Adaptive Voltage Regulation in Distribution Systems using Data-Driven Stochastic Optimization, IEEE

Improving the Efficiency and Sustainability of Power Systems Using Distributed Power Factor Correction Methods, MDPI sustainability

Leave a Reply