KYOCERA AVX has released the industry’s first automotive-qualified multilayer varistors (MLVs) equipped with the company’s patented FLEXITERM soft termination technology, which has been widely employed on a number of automotive-qualified multilayer ceramic capacitors (MLCCs) for more than 15 years. Designed to satisfy automotive industry demands for more robust component solutions, the new VCAS Series MLVs with FLEXITERM technology are engineered to reliably withstand severe flexing, vibration, and temperature cycling, enabling up to 5mm of mechanical board flexure over 3,000 temperature cycles extending up to 150°C with zero board flex failures, including internal cracks and depanelization, and no significant changes to electrical characteristics. Automotive-qualified MLVs with industry-standard terminations, on the other hand, generally support just 2mm of board flexure over 1,000 temperature cycles extending up to 125°C, which is often insufficient for preventing flex failures caused by the mechanical and thermal stresses incurred during assembly and operation.

KYOCERA AVX has released the industry’s first automotive-qualified multilayer varistors (MLVs) equipped with the company’s patented FLEXITERM soft termination technology, which has been widely employed on a number of automotive-qualified multilayer ceramic capacitors (MLCCs) for more than 15 years. Designed to satisfy automotive industry demands for more robust component solutions, the new VCAS Series MLVs with FLEXITERM technology are engineered to reliably withstand severe flexing, vibration, and temperature cycling, enabling up to 5mm of mechanical board flexure over 3,000 temperature cycles extending up to 150°C with zero board flex failures, including internal cracks and depanelization, and no significant changes to electrical characteristics. Automotive-qualified MLVs with industry-standard terminations, on the other hand, generally support just 2mm of board flexure over 1,000 temperature cycles extending up to 125°C, which is often insufficient for preventing flex failures caused by the mechanical and thermal stresses incurred during assembly and operation.

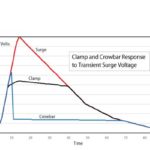

As such, the new VCAS Series MLVs with FLEXITERM soft termination technology provide increased reliability and outstanding mechanical and thermomechanical performance compared to competing solutions in automotive under-hood applications such as engine sensors with a direct connection to the battery rail, as well as in automotive audio circuits, aerospace, industrial, and downhole drilling applications, and IoT applications including smart watches, other wearables, and cleaning robots. In addition, these new MLVs exhibit high current and energy handling capabilities, super-fast response times, and multiple ESD strike capabilities, and provide high-reliability bidirectional overvoltage protection. They also provide EMI/RFI attenuation in their off state, which can reduce or even eliminate the need for additional EMC capacitors; exhibit lower insertion loss, lower leakage current, and unrivaled reliability compared to competing diode solutions; and are qualified to both the AEC-Q200 and VW 80808 specifications.

Currently available in four surface-mount cases sizes ranging from 0603 to 1210, the new VCAS Series MLVs are rated for five working voltages ranging from 5.6–30VDC, five clamping voltages extending from 18–67V, four energy transients spanning 0.1–1.5J, and operating temperatures as low as -55°C and as high as +150°C. They are also RoHS-compliant.

When subjected to the rigorous AEC-Q200 board bend and temperature cycling testing procedures, the new VCAS Series MLVs with FLEXITERM technology was proven to withstand up to 5mm of flexure (versus 2mm for MLVs with industry-standard terminations) over 3,000 temperature cycles extending up to 150°C with zero board flex failures and no significant changes to their electrical characteristics, which well exceeds the 1,000 cycles at up to 125°C AEC-Q200 testing requirement. This proven performance makes the series ideal for use in the signal and power lines of automotive, aerospace, and IoT applications subject to hazards including significant temperature variations, vibration, wave soldering, forced cooling, improper handling, the insertion and removal of PCBs from connectors, and high-density board configurations, all of which can result in board expansion, contraction, flexure, and cracking, and the depanelization of components mounted near the edges of the PCB, near flex zones, and near large, heavy components.

VCAS Series MLVs with FLEXITERM technology are packaged on 7” reels for compatibility with automated processing equipment, and the lead time for the series is currently 10 weeks.

Leave a Reply