Innoscience Technology will present two papers at the prestigious IEEE International Symposium on Power Semiconductor Devices (ISPSD) conference in Vancouver, Canada, May 22-25.

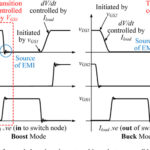

The first paper systematically evaluates the reliability and switching lifetime of a 650-V commercial GaN-on-Si HEMT fabricated on a 200mm (8-inch) CMOS-compatible process platform for a high-density PFC Boost power converter application. Innoscience’s engineers shows that by adopting Innoscience’s Strain Enhancement Layer (SEL)technology, a stable Dynamic RDS(on) (< 1.2x) during the 1000-hrs switching stress test is achieved, which is further confirmed by the wafer-level stress system. Device without SEL layer, on the contrary, shows a quicker degradation of the Dynamic RDS(on) that increases 18 times during the first 3 hours of stress. By performing Emission Microscope (EMMI) to detect the electroluminescence of device in situ during switching stress, scientists at Innoscience has highlighted that the SEL suppressed the hot carrier injection, which is believed to contribute to the increase of the Dynamic RDS(on) on samples without SEL technology.

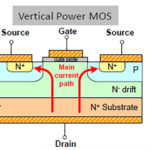

The second paper is titled ‘Dynamic RDS(on) and Vth free 15 V E-mode GaN HEMT delivering low switching Figure of Merit (sFOM) of 13.1 mΩ·nC and over’. The power devices discussed achieve record-low sFOM on commercialized 200 mm GaN-on-Si platform made for mass production. Although tremendous efforts have been made in low voltage GaN HEMT for consumer electronics, where power switches are typically below 40 V, the wide adoption of low voltage GaN HEMT still faces huge challenge as compared with its silicon counterpart as the contact resistance or parasitic capacitance proportion rises up as dimensions shrink down, the threshold voltage Vth decreases and the risk of false turn-on increases, off-state leakage current increases and results in large quiescent loss and long-term static and dynamic instability. All these issues hinder the wide acceptance of low voltage GaN HEMT in volume constrained portable electronics.

Innoscience shows that their InnoGaN withstands 1000 hours’ continual stress over wide temperature range with minimum parametric shift and continuous-switching stress in both hard-/soft-switching mode with negligible dynamic Ron and Vth shift. Device performance is further validated in buck converter with GaN HEMTs in half bridge configuration and demonstrates superior efficiency over 80% at tens of MHz. Thus, InnoGaN HEMTs rated for 15V unlocks the full potential of GaN power switches targeting for fast-speed high-frequency buck converter in tens of MHz with peak efficiency 90% with long-term system dynamic stability.

Dr Denis Marcon, General Manager, Innoscience Europe comments: “The two papers are highly detailed and include comprehensive test data as befits submissions to this industry-recognized, important IEEE conference. We hope that attendees will understand that Innoscience is clearly the leader in GaN devices produced on 8-inch silicon wafers, with fully-characterised performance and reliability data both for Low Voltage (LV) and High Voltage (HV) devices.”

Leave a Reply