The physical structure of the bimetallic element that provides thermal control is the difference between cantilever and disk bimetallic thermal control devices. This article begins by reviewing how bimetallic structures are made and operated. It then looks at how they are implemented in cantilever and disk thermal control devices.

Two dissimilar metals are joined together to form a bimetallic element. The important feature of the metals is their different rates of thermal expansion. The element consists of layers of dissimilar metals like brass, copper, or steel, joined together by welding, soldering, or another method. When initially fabricated, the two metal strips are usually the same length.

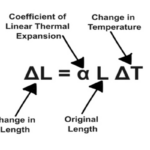

When the element is exposed to changes in heat, the metals react differently. If the temperature increases, the metal with a higher coefficient of thermal expansion gets longer compared to the metal with a lower coefficient of expansion. That causes the element to bend toward the metal with the lower coefficient.

The reverse happens for a decrease in temperature. The metal with the higher coefficient decreases more in length, and the element bends towards the metal with the higher thermal coefficient of expansion. The bimetallic element can be produced in a linear shape for cantilever devices or as a disk (Figure 1).

Cantilever

In cantilever bimetallic thermal control devices, one or both ends of the bimetallic element are restrained. That enables the control device to extract the maximum energy from the bimetallic element as it bends up and down in response to changes in temperature. In some designs, two bimetal elements are combined for increased sensitivity. Cantilever devices are split into categories based on their physical and electrical design characteristics including creep action versus snap action and conductive versus non-conductive, respectively.

A creep action device uses a single bimetal element that can close or open a circuit based on changes in temperature. The bimetallic element is fabricated to operate over a narrow temperature range between opening and closing.

The bimetal elements in snap action devices operate over a wider temperature range between the point where the switch opens and closes. These devices literally produce a snapping sound as the bimetallic element bends in response to temperature changes.

In conductive controls, the bimetallic element is also a circuit element and carries current. That means that the element’s self-heating from the current flow must be considered when designing and using these devices. When integrating these devices into an application, they must be derated to account for the self-heating effect.

In non-conductive thermal controls, the bimetallic element does not carry current. It provides the force to activate a mechanical switch, sometimes called a shunt. The shunt can get hotter when it’s carrying current, and since the shunt is in contact with the bimetal element, some amount of derating is needed. However, the derating for non-conductive bimetallic control devices is less than that needed for conductive designs.

Bimetallic disks

When the bimetallic element is formed into a hemispherical dome shape, it becomes a disk device. Disk bimetallic thermal control devices are inherently simpler in design than cantilever designs, and as a result, they are widely used.

The size of the bimetal disk varies. Common sizes include ½ and ¼ inches. While cantilever devices are available in conductive and non-conductive designs, disk devices are normally implemented as nonconductive designs and provide some level of electrical isolation between the switching action and the system.

For example, a snap action disk thermal device made using an ½ inch disk is available in a variety of hermetic packages and is rated for switching a maximum of 16A at 125 Vac for resistive loads (Figure 2). The differential range between switching on and off is less than 30 K. These devices are available with a choice of ±3 or ±5 °C operating temperature tolerances and have a dielectric withstand rating of 1,000 Vac for 1 minute or 1,800 Vac for 1 second.

Both cantilever and disk bimetallic thermal control devices are highly reliable. Cantilever devices are typically rated for 100,000 switching cycles at rated load and over a million switching cycles when switching a small control current. The 16A disk device pictured above Is rated for 100,000 switching cycles at 16A.

Summary

Cantilever and disk bimetallic thermal control devices are both based on harnessing the different thermal coefficients of expansion of two different metals like brass, copper, or steel. The strips of the two metals are mechanically connected using soldering, welding or another process and can be used to activate highly reliable switching actions based on increases or decreases in temperature.

References

A Complete Guide to the Working, Types, and Applications of Thermal Switches, Langir

Characteristics of Temperature Power Sensor and Disk Type Thermostat, Matsuo

The Bimetallic Strip Explained, Fictiv

The How-to Guide for Thermal Controls, Portage Electric Products

Leave a Reply