Just hearing the words “solenoid” and “relay” may conjure up visions of an ancient electromechanical word, now largely replaced by all-electronic devices, smart motors, and more. That almost makes sense, as these two components in various forms have been with us for over 150 years.

But don’t be fooled; both are still vital devices, and viable choices when there is a need for conversion of electrical energy to mechanical motion (solenoid), or need for one signal to control the on/off path of one or more other signals (relay). This FAQ will look at these two components, which have very different end-use functions but very similar underlying principles of physics.

Q: What is a solenoid?

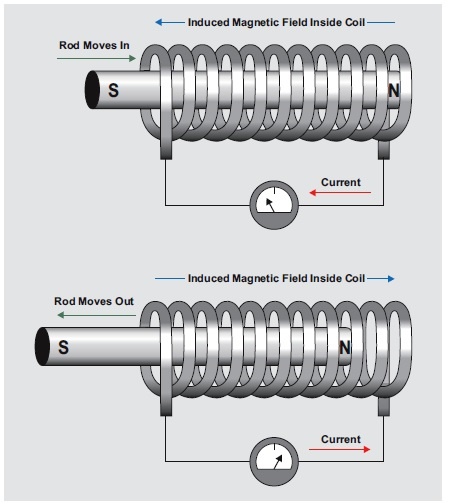

A: In simplest terms, it is a helically wound coil with a hollow center core along its axis. Within this core, there is a free-floating plunger of magnetic material which can slide along that axis, and is located off to one end or the other of the hollow center path.

When the coil is energized by either an AC or DC current, the plunger is pulled to the center by the resultant magnetic field. When the current is turned off, a spring or other mechanism scheme pulls the plunger back to its resting position (Figure 1).

Q: Where are solenoids used?

A: They are used almost anywhere there is a need for sharp, quick, linear motion over a limited range. Solenoids vary in size and power, of course, but typical sizes range from one-inch long to about six inches, with linear motion of the same range. Depending on the number of wire turns and the applied current, they can apply sub-ounce impacts to very large impact forces capable of punching holes in metal or forming rivet heads. Among the many solenoid applications are opening/closing locks, industrial machinery, vending machines…it’s a very long list of places, anywhere the project needs a sharp, solid, linear stroke or “punch.”

Q: How is the solenoid’s force determined?

A: The relationship among key variables has been known for over a hundred years, based on Ampere’s Law. Due to its importance and the nature of its operating principles, the solenoid has been studied extensively and analyzed with high accuracy. In the ideal case:

where N is the number of turns, A is the cross-sectional area of the armature, g is the gap size, μO is the magnetic permeability of air, and i is the current applied.

Note that the strength of the force is proportional to the square of both the current and the number of turns. While this ideal equation does not take into account coil fringing losses, coil imperfections, and other real-world issues, it is a good starting point.

Q: How does the electrical circuitry drive the solenoid?

A: Like most magnetic devices, the solenoid is a current-driven device, as shown by the basic equation. Therefore, it is best supplied by a true current source. However, since many applications have a voltage source (rail) rather than a current source, solenoids are also specified in terms of their DC resistance, so a voltage source can be used—as long as it can supply the needed current as determined by Ohms law.

Q: Does it matter if you use a current source versus a voltage source?

A: Yes and no. Many successful solenoid design-ins use a voltage source that can supply the needed current. However, it may be hard to drive that current properly from the voltage source, since the solenoid’s relatively high transient-current demand means that the voltage source may “dip” as it tries to supply that current pulse unless it is a stiff source with a very low lead-wire resistance (such as the AC line). For this reason, many designs use a current source rather than a voltage source if they can.

Q: What are some other solenoid-drive issues?

A: In general, solenoids use a lot of power relative to the rest of the system, and they dissipate this power as heat. Thus, they can get hot, which is a burden to the system and affects solenoid life. Note that if the application is a pulsed, low-duty-cycle situation such as in a vending machine, this may not be an issue of concern. However, it can be a problem in a high-volume, high-rate application such as an industrial production line.

Q: What are the other downsides of solenoids?

A: In addition to their fast-transient and relatively high current requirements and associated self-heating, they are difficult to use for precise operation of force or repeatability. However, the use of smart drivers plus position feedback via Hall-effect devices has greatly improved the situation (more on this later).

Q: What can be done to enhance and improve solenoid operation?

A: Quite a bit. First, recognize that there are two basic solenoid operating cases. There is the basic impact mode, where the device is energized, the plunger moves and impacts with force, and the solenoid is de-energized. Again, this might be a vending machine dispensing a product or opening a door. In the second mode, the solenoid is energized and is held in that mode for a relatively long period, such as to keep a door unlatched as people pass through.

In cases where the solenoid is held in the energized position for more than a brief stroke, the unit usually becomes hot, and it certainly consumes significant energy. However, the physics reality is that the amount of current needed to hold a solenoid is far less than the activation current—roughly half or less—so a smart driver can activate at full current, the switch to a hold current at a much lower level.

Q: What’s a smart driver?

A: While it is possible to drive a solenoid by simply connecting to a suitable voltage rail or current source, a smart driver can do much more in terms of functions and performance. From an electrical perspective, a solenoid is similar to a motor, as both are current-driven, highly inductive loads, and the driver requirements are similar as well. Many of the components used for motor-coil control (usually MOSFETs) and their drivers are used directly or in variations as solenoid drivers.

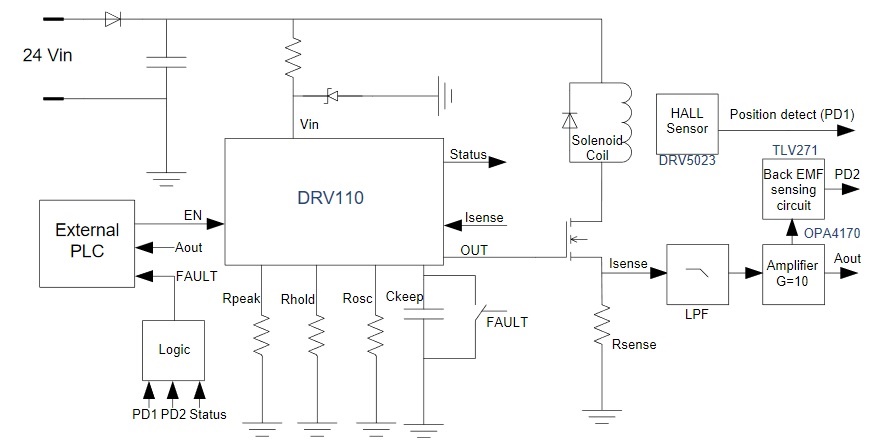

For example, the Texas Instruments DRV110, (Figure 2), is a power-saving solenoid-current controller which operates from a 24-V DC rail. It is a true current source that controls the solenoid current during peak and holds modes for lower power and thermal dissipation by using PWM drive control via an external MOSFET.

It allows the designer to adjust peak current, “keep time” at peak current, hold current, and automate switchover from peak-to-hold current mode at the end of plunger movement. Further, it has provision for the addition of an external Hall-effect sensor to indicate the plunger position. Finally, it adds sensing to detect hard and soft fault conditions (shorted or open coils, blocked plunger movement), which are possible internal and external failure modes.

Although such an IC-based driver requires more external passive-support components than a simple power rail in series with the solenoid, it offers far superior performance. Of course, there are many low-end applications, such as toys, where a basic power-source loop without any electronics is adequate and cost-effective.

The next part of this FAQ will examine the relay, a device that shares many electromagnetic characteristics with the solenoid, but has a very different construction and functionality.

Reference

Texas Instruments TIDU578, “Current Controlled Driver for 24-V DC Solenoid With Plunger Fault Detection”

I appreciate you helping me learn more about Solenoids. I am not that familiar with it but based on your statement, it is a wound coil and its function is for the machinery for a linear motion. Oh my, I never dreamed of becoming an engineer but here am I, trying to understand this, hahaha! Nevertheless, this is one of the very informative posts I’ve ever read.