Brushless DC and stepper motors may get more attention than the classic brushed DC motor, but the latter may still be a better choice in some applications.

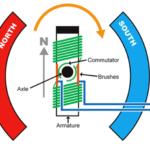

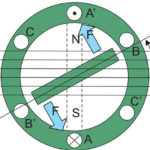

The brushed motor is available in sizes from tiny ones providing a few inch-ounces of torque through hundreds of horsepower and has been used successfully for over 100 years. It does work well in many installations. The brushed DC motor is so simple, and its operation is so visual that it is widely available as a basic science kit for STEM programs, retailing for $10 to $30 (Figure 1); all you need to do is connect a battery to make it run.

Besides the control issues, another shortcoming of the brushed motor is that the commutation contacts will eventually wear down and be unusable. The debris of this wear-down also creates conductive dust. The brushes are often made of graphite, but other more-costly, more-rugged materials are used in some specialty motors; larger motors are often designed with the brushes set into “sockets” to be removed and replaced as needed.

The brush-created conductive dust can be a problem from both an environmental standpoint and its potential for causing nearly untraceable short circuits in associated circuity and circuit boards. Further, the on/off nature and sparking at the brushes as they contact and switch at the commutator can create EMI and exceed allowable regulatory limits depending on the size of the motor and the application.

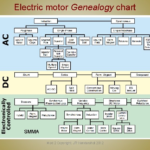

Given these issues, why would anyone choose a brushed motor given its issues related to brushes or contact fingers and challenges of performance, except for lower cost or use in a legacy application? Most designers intuitively consider BLDC or stepper motors – and only those – because they offer a good combination of benefits. They are offered with different voltage, current, torque, other ratings, hardware drivers, and control algorithms in software or firmware. These drivers are also offered with GUIs that make it easy to set the desired performance attributes (speed, acceleration/deceleration profiles, and responsiveness.)

It seems that it just doesn’t make sense – at first. Yet despite the apparent advantages of BLDC motors, there are reasons why most BLDC motor vendors also offer brushed motors, and it’s not just that they may be less expensive components in many cases. The reality is that with appropriate motion-control ICs, even brushed motors can deliver effective performance and velocity/torque control and offer different tradeoffs in size, weight, efficiency, and other attributes compared to brushless motors.

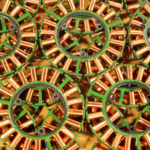

This is clearly shown by an article in Medical Design Briefs about motor selection for a sophisticated portable (home) infusion pump, “Every Drop Counts: Designing Motors to Optimize Home and Ambulatory Infusion Pumps.” This linear peristaltic-pump mechanism is an advanced application where low cost is certainly not the primary criteria of the selection process (although it is one of them, of course), while size and noise were important. Small size, weight, low noise, and an overall “non-threatening” packaging were key issues as the device was used in the home (Figure 2).

The article clearly spells out the relative merits of a coreless brushed DC motor versus the BLDC (and the stepper motor, a BLDC variation) with respect to efficiency, compactness, lifetime, noise level, and reliability for this specific application (Figure 3). It includes numbers for the analysis of the design and sizing of the motor versus flow requirements and clarifies why the venerable brushed motor, albeit in a more-modern “coreless” configuration, was the best choice here, where compactness and quiet performance were key design priorities. (Obviously, an analysis for a spacecraft application would include these and other attributes, but with different priorities and weightings).

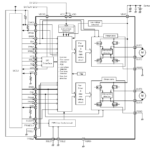

The next part of this article looks at some ICs designed to drive brushed DC motors and enable advanced performance from these motors.

Related EE World Content

- Driving brushed and brushless DC motors

- Speed Controller for Brushed and Brushless DC Motors

- Brushed DC Motors in Industrial Versions

- Basics of motion-control profiles, Part 1: Context

- Basics of motion-control profiles, Part 2: Ramp profiles

- Basics of motion-control profiles, Part 3: Implementations

- Motor fundamentals and DC motors

References

Machine Design, “Controlling Brushed DC Motors Using PWM”

Medical Design Briefs, “Every Drop Counts: Designing Motors to Optimize Home and Ambulatory Infusion Pumps”

Portescap, “Miniature Motors Deliver Big Performance for Medical Analyzers”

Portescap, “Selecting Miniature Motors for your Medical Devices”

Portescap, “Brush DC Motor Basics”

Portescap, “Controlling Brushed DC Motors Using PWM – Optimal Frequency, Current Ripple and Life Considerations”

Toshiba, TB9053FTG and TB9054FTG Data Sheet

Leave a Reply