by Sol Jacobs, Tadiran Batteries

Battery makers have devised chemistries that put a lot of energy in a tiny volume.

Generally speaking, every penny counts when it comes to designing devices for a mass consumer market. That’s one reason smartphones use relatively inexpensive, rechargeable lithium polymer batteries for power. Constructed from a thin, flexible material, lithium polymer batteries can reduce product profile while satisfying the power requirements of a device that typically gets replaced every few years.

There’s another kind of lithium battery that can sometimes be an excellent power source for consumer devices: a consumer-grade rechargeable lithium-ion (Li-ion) battery, which is relatively inexpensive and readily available. But these cells have a limited service life, about five years and 500 recharge cycles.

Short-lived rechargeable Li-ion batteries don’t work well for industrial applications, which are often characterized by the need for long battery life. Consequently, battery makers have developed more robust Li-ion cells. One in this category is the TLI Series Li-ion rechargeable battery. The AA-sized cell can last for up to 20 years and 5,000 full recharge cycles while delivering 15-A pulses. These small but powerful batteries can also work and recharge at extreme temperatures (-40 to 85° C), have a low self-discharge rate of 5% per year, and are constructed with a glass-to-metal hermetic seal to resist leakage and corrosion.

Remote wireless devices are predominantly powered by bobbin-type lithium thionyl chloride (LiSOCL2) batteries. These cells are characterized by the highest capacity and energy density of any lithium chemistry. Certain brands of bobbin-type LiSOCL2 batteries can operate for up to 40 years and have an extremely wide temperature range. These qualities make them candidates for long-term deployment in applications drawing a low rate of current where the device spends a majority of its time in a “dormant” state. The low-rate design of bobbin-type LiSOCL2 batteries makes them poorly suited for applications that draw high continuous current. But they can be optimized to handle these applications by including a patented hybrid layer capacitor (HLC). The HLC helps deliver high-current pulse loads that often arise during the initiation of data acquisition and transmission.

The choice of a power supply can become more complicated for applications that require both high pulses and high continuous current. Typical applications in this category include single-use devices for military and aerospace, surgical power tools and safety devices, such as automatic external defibrillators (AEDs), that can remain dormant for years but must operate reliably in a life-and-death emergency.

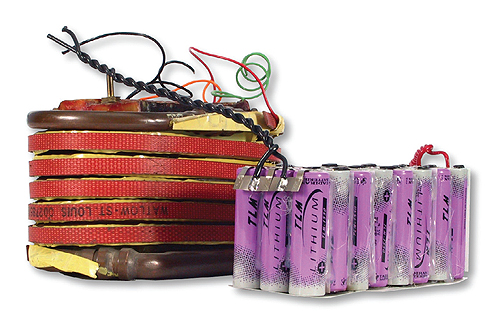

Battery makers have developed technologies to meet these challenging power requirements. One development in this area is the TLM Series lithium metal-oxide battery. This battery is constructed with a carbon-based anode, a multi-metal-oxide cathode and an organic electrolyte.

TLM Series batteries can operate for up to 20 years with an annual self-discharge rate of less than 1% per year. These small but powerful cells feature a nominal voltage of 4 V and up to 2 Wh of energy, with a discharge capacity of 135 to 500 mAh. They are capable of handling 5-A continuous loads and up to 15-A pulses. These batteries also offer a wide operating temperature range (-40 to 85° C), and comply with MIL-STD 810G specs for vibration, shock, temperature shock, salt fog, altitude, acceleration (50,000 g) and spinning (30,000 rpm). TLM batteries also conform to UN 1642 and IEC 60086 standards for crush, impact, nail penetration, heat, over-charge and short circuit, and can ship as non-hazardous goods.

Examples help illustrate where TLM Series batteries can provide benefits. In one case, an air-to-ground missile originally used a battery pack consisting of 19 silver-zinc cells. Substitution of high-power lithium metal-oxide cells reduced battery pack size by 30% and weight by 75%, 2.2 Kg versus 0.5 Kg. The new battery pack also had 3.5 times greater energy density. Use of a TLM Series battery pack saved space by eliminating the need for a squib, gas generator and heater that a silver-zinc battery pack required.

In another case, BAE Systems deployed TLM Series batteries as part of a 60-mm mortar guidance system for a Darpa initiative called ODAM (Optically Directed Attack Munitions). TLM-1530-HP lithium batteries powered the system’s laser-guided optical seekers. TLM Series cells can operate at much colder temperature (-40 ° C) and have a much longer shelf life (20 years versus 5 years) than CR-2 consumer batteries that were also candidates for this application.

Another common application for TLM Series batteries is in powering surgical screwdrivers and power tools. These applications require a small, ergonomic power supply with the capacity to deliver a high rate of current. Many such handheld medical tools formerly used Alkaline batteries, which are extremely bulky and self-discharge at a high rate.

BioAccess, a surgical device manufacturer, made TLM Series lithium batteries an optional power supply upgrade for its surgical drills. The drills previously used Alkaline battery packs exclusively. The Alkaline batteries performed well and were reliable, but heavy. Substituting six AA-size TLM-1550HP batteries reduced battery weight by more than a third (36%) and took up only 40% of the original volume. An equivalent Alkaline battery pack would need 15 AA-size Alkaline cells to do the same job as six AA-size TLM cells.

Use of a TLM-1550-HP battery pack also permitted the surgical drill to deliver faster drilling speeds, more active drill time (30 to 40 sec at a time for up to 20 to 30 cycles), more instantaneous power and more stall torque. The overall result was more efficient drilling cycles with less operator fatigue.

Resources

Tadiran Batteries

www.tadiran.com

Leave a Reply