by Ryan Smoot, CUI Devices

Fans are a crucial feature of many electronic systems, maintaining operation within a certain temperature range, while ensuring electronics are working at their optimum level across their operational lifetime. Key to a fan’s design is the consistent running of the bearing on which the rotor spins. The sleeve bearing and the ball bearing might be the two designs most commonly used, but what are the pros and cons of each and is there a third option?

Sleeve bearing fans have a simple design, they are rugged, cost-effective, and not too noisy. However, their design of a central shaft enclosed in a sleeve assembly means they are more liable to erosion and lubricant leakage which leads to a lower MTBF than ball bearing fans.

The ball bearing fan on the other hand, with its more complex design employing a ring of balls around its shaft, is less prone to deteriorate and operates at higher temperatures in any orientation. However, this leads to a design that is more expensive and noisier than the sleeve bearing option.

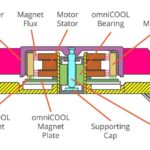

The CUI Devices’ omniCOOL system uses magnetic rotor-balancing together with an improved sleeve bearing, it offsets the drawbacks of other fan designs by working like a spinning top. The magnetic structure results in a fan that can be deployed at any angle, with minimal friction (no lubricants or washers required), less noise, and can function at higher temperatures.

Leave a Reply