Billed as the most comprehensive battery manufacturing event, the Battery Show combined with the Electric & Hybrid Vehicle Technology Expo in Novi, Mich., featured over 750 exhibitors and 150 conference presenters, with crowded aisles playing host to more than 14,500 attendees. Here are a few of the sights that caught our eye while checking out the exhibits.

Even electric vehicles get hot rodded

Legacy EV specializes in aftermarket EV applications, offering products like integrated EV systems, certified EV technician training programs, and EV design consultation for businesses. It is one of the places you can go if you want to put, say, a Tesla electric drive in a conventional ICE chassis. This hot rod at the Legacy booth is an example of what’s possible with a Legacy EV conversion kit. Besides electric drives from Tesla, Legacy also handles units made by Cascadia Motion, NetGain, UQM/Danfoss, and Revolt Systems. Other notable builds employing Legacy kits include a 1971 Electric Chevy C-10 built by Old Town Auto featuring 253 hp and 356 ft lbs of torque, a 1965 Electric Volkswagen Bug equipped with 127 hp, 173 ft lbs of torque, and 91 miles of range; and a 1966 electric Caddy is powered by three Netgain Hyper 9 Motors and a custom lithium-ion battery pack.

When the fan is fed by an orange wire

Orange wires in electric vehicles mean high voltage. And the orange wires on these fans from EMP (Escanaba, Mich.) mean the fans can work directly from the 850-V powertrain bus voltage. EMP says these Smart Flow FiC-15 e-fans are currently being integrated into several FCEV and BEV cooling applications. They’re designed for use in medium and heavy-duty on-highway vehicles and electric industrial vehicles. These fans can run at 500 – 850 V with up to 3 kW of power. The HV fans are CAN controlled for variable speed and include diagnostic capabilities.

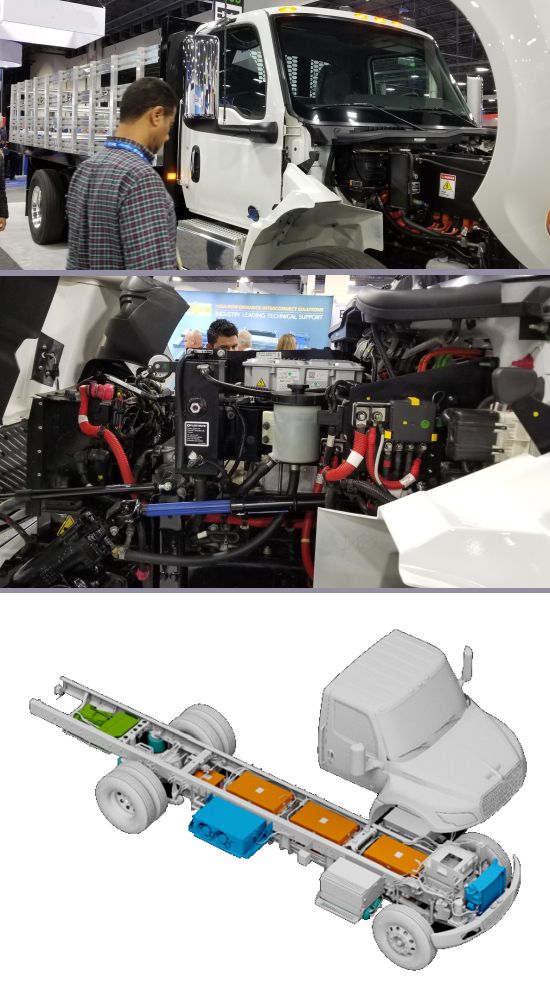

Heavy duty trucks go electric

This is what a Navistar International truck looks like these days. More specifically, this is an eMV Series which is a little over 30 ft long and carries a 255 kW electric motor developing 2,355 Nm of torque at 1,000 rpm. The truck is based on the diesel MV but with air tanks and air-bag management, as well as a 210 kWh battery pack regen braking, and a fast-charge capability of up to 125 kWh. The electric truck is also said to have a 135-mile range.

Big wheels keep on turning

What you see here is a truck wheel, held up by Simon Pinter of Computer Aided Technology (Buffalo Grove, Ill.), that has been 3D printed out of ABS in two parts and then welded together. The firm used a Stratasys F900 large-volume printer to do the wheel which is a form-and-fit type model. Computer Aided Technology provides equipment and expertise for product development efforts.

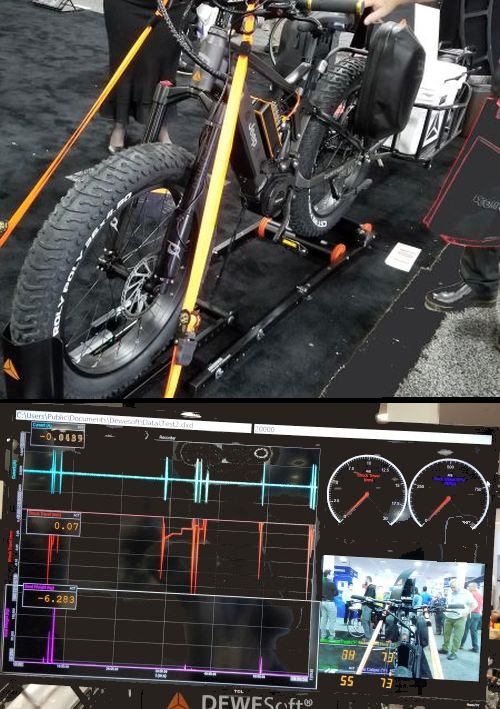

Development cycle for a motorcycle

Dewesoft is a provider of data acquisition equipment. So the company put some of it to work on an electrified motorbike and a trailer carrying a cooler. It instrumented the bike with sensors for factors such as battery current and temperature, wheel speed, temperature inside the towed cooler, and a few other things. The detailed readouts are visible in the screen shot below. The view from the driver’s seat can be discerned from the short video we shot of the demonstration.

Formula E at the battery show

There was one Formula E car at the Battery Show. Fielded by Jaguar and appearing at the Dow booth, it features a maximum power limited by Formula E specs to 250 kW, equivalent to 335 hp and 22-in Michelin Pilot Super Sport tires, among other things. It’s 0 – 60 mph speed is 2.8 sec and has a max speed of 174 mph. The Generation 2 lithium-ion battery (848 lbs, 52 kW) sits in a carbon fiber safety cell and has the usable energy of 5,000 fully charged mobile phones, Jaguar says. The silicon-carbide module I-TYPE inverter is from Jaguar Racing. Visible in the image is the new FIA Halo head protection device, with its LED light strip. When the lighting on the Halo glows blue, the car and driver are in Attack Mode. The Halo glows magenta when the driver has activated FanBoost, allowing fans to follow their strategy.

Excavators go electric

Not many makers of electric powertrain equipment for the off-road industry can claim to have a signature cocktail, but that is the case for Turntide Technologies, Sunnyvale, Calif. The firm celebrated its 300,000th vehicle milestone by serving its cocktail at its Battery Show booth. (For the curious, the cocktail consists of 1 oz vodka, 0.5 oz triple sec, 0.5 Blue Curacao, ice, and a lemon twist.) On display at the Turntide booth was its Gen4 Size 2 ac induction motor controller (top left), an eCP80 high flow 24-V electric water pump with variable-speed control via an integrated motor controller (top right), a Gen5 Size 9 high-voltage (128 to 450 V output) motor controller (below right), and a couple Hyperdrive batteries, which are basically lithium-ion battery packs combined with a BMS. The battery at right is a standard 4.94 kWh/111 Ah device.

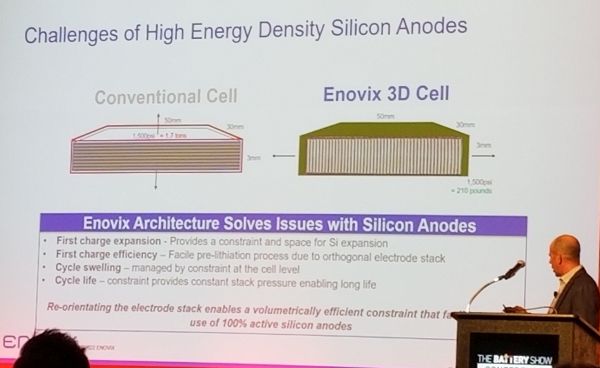

Ode to silicon anodes

As you might expect, there were several new battery technologies highlighted during the conference and show. In one conference session, Enovix discussed its silicon anode technology. Batteries carrying silicon anodes have a reputation for swelling during the charging process, a drawback Enovix claims to have solved by reorienting the electrode stack and using a pre-lithiation process. On the show floor, Our Next Energy (ONE) in Novi, Mich. debuted a “anodeless” battery cell with an energy density of 1,007 Wh/l. Despite the anodeless moniker, the cell retains a positive and a negative pole. But its anode (metal) doesn’t use graphite, thus eliminating the need to use classic production equipment to process this material. This is said to significantly reduce manufacturing costs to below $50/kWh.

Leave a Reply