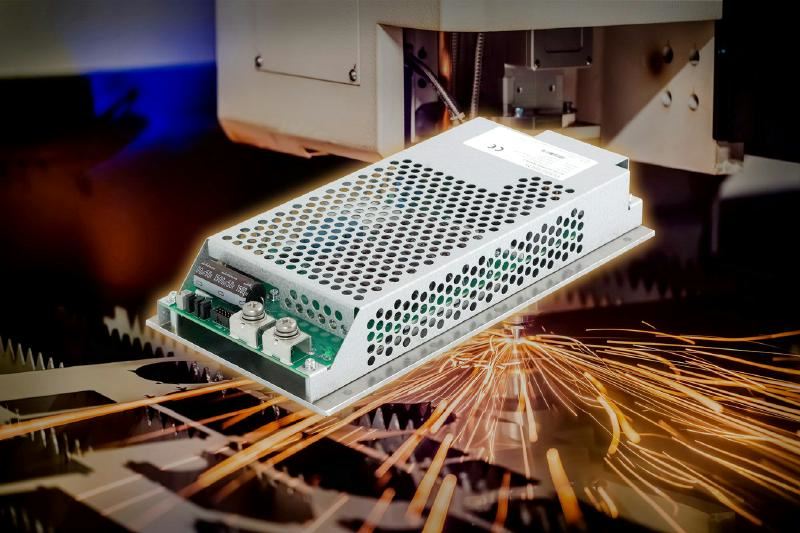

Powerbox has announced the release of a new 700W power supply for industrial applications, the OFI700A. Optimized for conduction cooling, the OFI700A delivers high-performance levels across a baseplate temperature range of -40 to +95 degrees C, without the use of a fan. The power supply operates with a wide universal input range from 85 to 264VAC with power factor correction (PFC) and is available with DC outputs of 12V, 28V (adjustable to 24V), or 48VDC. A 12V auxiliary is also provided.

Powerbox has announced the release of a new 700W power supply for industrial applications, the OFI700A. Optimized for conduction cooling, the OFI700A delivers high-performance levels across a baseplate temperature range of -40 to +95 degrees C, without the use of a fan. The power supply operates with a wide universal input range from 85 to 264VAC with power factor correction (PFC) and is available with DC outputs of 12V, 28V (adjustable to 24V), or 48VDC. A 12V auxiliary is also provided.

In many industrial applications cooling of the dissipating elements relies on the use of fans and blowers. But there are applications where it is not possible or even allowed to use active ventilation. In harsh environments or in applications where the required reliability level imposes the need to remove all possible risks of failure, fans and blowers are not allowed. A sealed box such as is required for laser-cutting is but one example, but there is also a growing demand for equipment installed in supervisory rooms or even offices that for the comfort and health of the employees, generated noise is simply not allowed or needs to be very much limited.

Conduction cooling requires very specific building practices and the PRBX OFI700A has been designed to guarantee optimal heat transfer from the dissipating components to the baseplate, delivering a high level of performance within an operating temperature of -40 to +95 degrees centigrade at the baseplate. Depending on the assembly method and the overall cooling conditions, a derating may apply as specified in the technical documentation.

To cover a wide range of applications, the OFI700A operates with a wide universal input range from 85 to 264VAC. The unit includes a PFC with a coefficient of 0.95/0.92 (110VAC/230VAC). For applications powered by a DC bus e.g., mining equipment, the OFI700A operates from 120 to 350VDC.

The OFI700A is available in three versions of single output DC voltage, 12V/58.4A; 28V/25A, and 48V/14.6A. The output voltage can be adjusted using the provided onboard potentiometer. For example, the 28V output can be adjusted from 22.4V to 33.6V, covering the 24V applications. An additional voltage of 12V/0.1A is provided for auxiliary functions.

For applications requiring 1+1 redundancy, it is possible to connect two units in parallel, adding an external diode to protect the unit. Using a diode for this purpose is a simple solution but it increases power losses which depending on the output current could be as high as 30W. So, to maintain the highest level of efficiency when operated in redundancy mode, an ‘option O’ OFI700A version is available with active ORing circuitry deploying high-performance FET technology. In this version, the power losses are minimized to an excellent less than 1.5W.

For safety, the OFI700A has an IN/OUT isolation of 3,000VAC and IN/FG of 2,000VAC. Output isolation to FG is 500VAC. The power supply includes overcurrent protection with auto-recovery, over-voltage, and over-temperature protection.

The OFI700A board includes easy access to auxiliary functions via onboard connectors, namely: Remote Control, Output Voltage Sensing, DC-OK, Inverter Operation Mode (IOG), and auxiliary 12V.

The OFI700A has endured shock and vibration testing as specified in MIL-STD-810H. In that respect, the products have been tested to levels far above normal operating conditions and are specified to sustain a high 20G vibration level during transportation.

In its open frame format, the OFI700A measures 126 x 38 x 250mm (4.96 x 1.5 x 9.84 inches) and weighs 0.95kg max. An optional metal cover is available, adding just 2mm to the height and 150 grams to the weight (Option N).

The OFI700A is certified in accordance with UL62368-1, C-UL (equivalent to CAN/CSA-C22.2 No.62368-1), EN62368-1.

The OFI700A series has a full three-year warranty and conforms to the European RoHS, REACH, and Low Voltage Directives. The product carries the UL, CE, and UKCA marks.

Leave a Reply