When an application requires fast motion with a stroke over a couple of inches, a brushless linear motor stage will meet the needs of long travel and fast motion when coupled with a motion control system with servo amplifiers and a motion controller. Brushless linear motor stages can be coupled as a gantry for pick-and-place manufacturing or inspection equipment. The fast motion allows for high throughput when manufacturing or examining parts.

When an application requires fast motion with a stroke over a couple of inches, a brushless linear motor stage will meet the needs of long travel and fast motion when coupled with a motion control system with servo amplifiers and a motion controller. Brushless linear motor stages can be coupled as a gantry for pick-and-place manufacturing or inspection equipment. The fast motion allows for high throughput when manufacturing or examining parts.

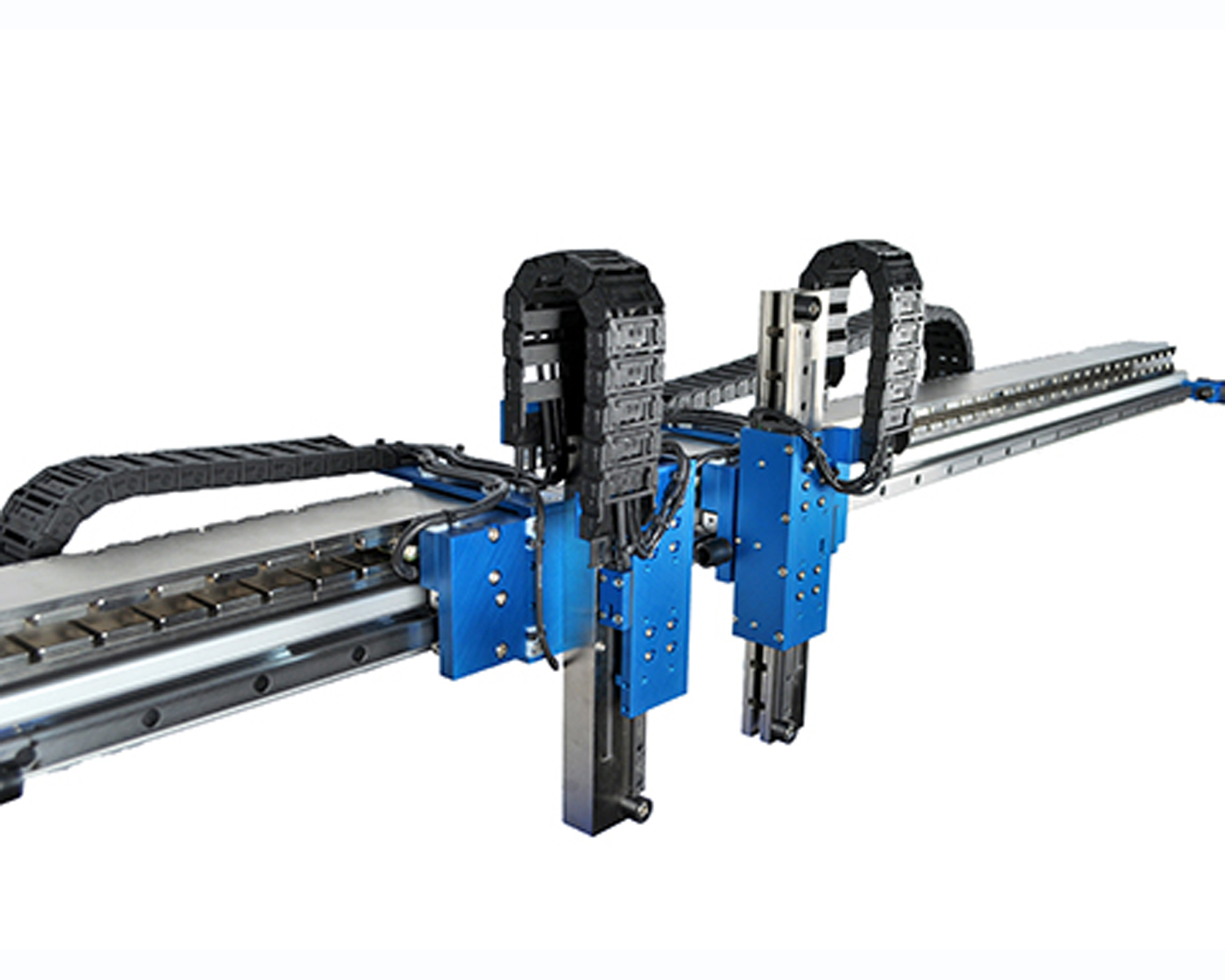

The Four-Axis Gantry (YY’ZZ’) is a four-axis positioning stage that consists of two SRS-007-03-006-01 brushless linear motor stages; each vertically mounted to two independently moving horizontal linear axis. It is ideal for applications that require multiple independent motions on a single travel plane.

Each horizontal linear axis uses a BLDM-D04 H2W brushless linear motor to generate a continuous/peak force of 16.5 lbs. [73.6 N]/49.0 lbs. [220 N] with each moving table capable of a total stroke length of 47.1 in [1196 mm]. Each moving table has an independent non-contact 1.0-micron resolution encoder head reading a single encoder scale allowing for precise positioning and is guided by a rigid recirculating ball linear bearing block sharing a single linear bearing rail.

Each vertical axis (SRS-007-03-006-01) uses a BLDM-B04 H2W brushless linear motor to generate a continuous/peak force of 6.2 lbs. [27.8 N]/18.7 lbs. [83.3 N] with a total stroke length of 7.0 in [177.8 mm]. The non-contact 1.0-micron resolution encoder allows for precise positioning. A rigid recirculating ball linear bearing guides it.

The entire stage is assembled on a single piece of aluminum extrusion, thus reducing the overall size and weight of the system. Some provisions allow customer cables to be routed within the cable carriers. It has end-of-travel rubber bumper stops. A home positioning sensor, end-of-travel sensors, and custom mounting holes on the moving tables are available upon request.

H2W Technologies is dedicated to the design and manufacture of linear and rotary motion products that are used in the motion control industry. The complete line of linear electric motors includes single and dual axis linear steppers, DC brush and brushless linear motors, voice coil actuators, and AC induction motors. Also offered is a complete line of ball screw, lead screw, and belt-driven positioning stages.

Other motion control products include limited angle torque motors for compact, limited angular excursion rotary servo applications, 3 phase brushless rotary servo motors with matching digital servo amplifiers, and permanent magnet linear brakes for fail-safe, zero power braking for baggage handling and people moving applications as well as amusement park rides.

With over 75 years of combined experience in the linear and rotary motion field, the H2W Technologies team of engineers offers the optimal solution to the most demanding motion control requirements.

Leave a Reply