Fuel cells are increasingly being used in stationary power applications such as backup power, microgrids, and renewable energy systems. This is part two of a three-part FAQ series and digs into a wide variety of fuel cells in stationary power applications ranging from low power systems for residential backup power to the use of large-scale reversible fuel cells to maximize the benefits of renewable energy systems. Part one of this FAQ series on fuel cells reviewed “Fuel Cell Technologies and Operating Characteristics.” In part three, the growing use of fuel cells in transportation applications, including heavy-duty buses, trucks, trains, planes, and ships, will be discussed.

Microgrid and backup power applications

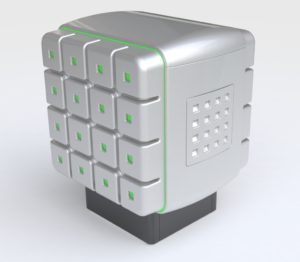

The first Redox Cube solid oxide fuel cell from Redox Power Systems is a 25kW, natural gas-fueled, stationary power system. With roughly 35 cubic feet (1 cubic meter) and weight under 1,000 pounds (450 kg), the Cube can be installed outdoors or indoors. The system takes advantage of the company’s proprietary lower temperature, higher power cells, and stacks, as well as an innovative fuel processor. The Cube produces DC and can be configured for different DC output voltages depending on the application. AC power requires an inverter. The Cube is designed with mass production in mind, using a modular approach whereby key components can be tailored and packaged to deliver desired power levels.

The Redox Cube operates at about 650°C (1,200°F). Redox is working to lower the operating temperature even further to about 400 to 500 °C while maintaining high power density to add features that will make Redox Cube even more robust and versatile. Lower operating temperatures allow the use of lower-cost materials, thus, reducing capital costs. Lower temperatures also dramatically improve the system’s lifetime. With the addition of a heat recovery module, combined heat and power (CHP) operation can boost the Cube’s total electrical and thermal efficiency in excess of 80% percent.

Ballard Power Systems has sold an initial order of 500 2.9kW FCgen-1020ACS fuel cell stacks to adKor GmbH and SFC Energy AG, to be integrated into adKor’s Jupiter backup power systems for deployment at radio tower sites in Germany through the end of 2021.

Contracts have been awarded to adKor for the supply of fuel cell backup power systems to support an initial tranche of 500 radio tower sites in Germany – with the potential for up to 1,500 radio tower sites, adKor has sub-contracted a portion of the work to SFC Energy. As a result, adKor and SFC Energy have signed development partnership and licensing agreements to share production activities for the supply of Jupiter systems and develop product line extensions. Each Jupiter backup power system utilizing from 1 to 3 of these fuel cell stacks. German regulations require radio tower sites to have a minimum of 72 hours of backup power to ensure radio communications for critical users in a power blackout.

Plug Power Inc. offers its GenSure HP (high power) platform, a line of zero-emission stationary fuel cell systems designed for high power backup power applications. This product line is focused on the largest segments in the $15 billion stationary power available market. Initially available in power output configurations ranging from 500kW to 1.5MW, the new GenSure HP platform offers a reliable and rapidly deployable solution for power-hungry data centers, energy storage systems, microgrids, and other high power commercial facilities.

GenSure HP hydrogen fuel cell systems are made up of Plug Power’s 125kW ProGen fuel cell engines, commercially launched in February of 2020. Initial configurations include power outputs of 500kW, 1MW, and 1.5MW, with all systems housed in standard ISO containers for ease of packaging and deployment. GenSure HP solutions are modular and scalable to meet higher capacity requirements, making them appropriate for a wide variety of high power applications ranging from as low as 100kW to those requiring multiple megawatts.

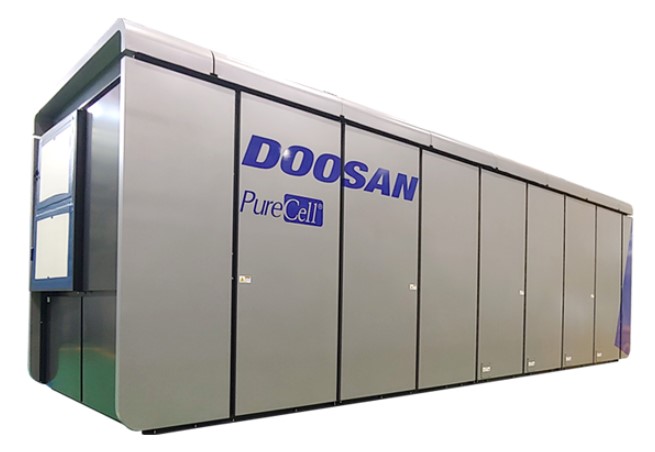

Doosan Fuel Cell has PAFC (Phosphoric Acid Fuel Cell) technology, which leverages liquid phosphoric acid as an electrolyte. Doosan’s technology provides benefits of durability, fuel flexibility, and fast response to meet energy needs in real-time. The natural gas/LPG model is designed to operate at dual-mode regions where energy access is lagging. Doosan’s PAFC can use LPG as a backup fuel to supply electricity and heat. It’s best suited for emergency power supply.

And Doosan Fuel Cell recently signed an agreement with Hyundai Motor Company to build distributed power generation systems for microgrids. Under this agreement, Doosan Fuel Cell and Hyundai Motor Company will produce PAFC and Polymer Electrolyte Membrane (PEM) fuel cells, respectively.

Microgrids go to sea

ABB has developed a compact size DC-based power distribution system to offer hybrid power efficiencies to smaller vessels. The recently launched Onboard Microgrid can enable up to 20% energy efficiency in larger vessels. With the launch of the new compact-size solution, ABB makes similar efficiencies achievable for smaller, lower-power vessels operating over short distances. Onboard Microgrid can be used for vessels running on batteries, fuel cells, or fuel cell/battery hybrids.

Similar to ABB’s Onboard DC Grid™, Onboard Microgrid allows for the flexibility to draw on multiple energy sources and variable speed drives to optimize operating efficiency and, as a result, cut emissions. Onboard Microgrid connects all DC links and distributes the power through one main DC circuit, providing significant power savings and optimizing the vessel’s propulsion.

In addition, Onboard Microgrid reduces the footprint and weight of the electrical equipment on board by eliminating the need for bulky transformers and main switchboards. That leaves more space on the vessels and provides greater flexibility in positioning the system on board.

Reversible fuel cells and renewable energy systems

FuelCell Energy, Inc. is working on performance improvements to advance the commercialization of its reversible solid oxide fuel cell (RSOFC) systems. An RSOFC system is a hybrid operating system that performs water electrolysis for hydrogen production, stores the hydrogen, and then produces power by using the produced hydrogen.

FuelCell Energy’s solution converts intermittent and excess power from renewable energy sources during periods of low power demand into hydrogen stores the hydrogen on-site for long periods of time. It then uses this as a fuel source to generate clean power when needed during high power demand. This megawatt scalable solution is expected to provide long-duration storage and compares very favorably against other technologies.

Also targeting renewable applications, Ballard Power Systems is working with Hydrogene de France (HDF Energy), an independent power producer dedicated to renewable power generation, for the development and integration of a multi-megawatt (MW) scale fuel cell system into HDF Energy’s Renewstable® power plant designed for stationary power applications.

HDF Energy’s Renewstable® power plant is a multi-MW baseload system enabling large-scale storage of intermittent renewable wind or solar energy in the form of hydrogen – through the process of electrolysis – as well as electricity generation using that hydrogen feedstock together with a fuel cell system. This power plant can produce zero-emission power on a 24/7 basis from intermittent renewable energy to support electrical grids.

The integrated architecture of renewables-electrolysis-hydrogen storage fuel cell systems can deliver reduced energy costs, improved grid stability and resiliency, increased penetration of renewables, and greater energy independence. HDF’s Renewstable® power plant may also be used to store green hydrogen for use in other applications, such as zero-emission fuel for fuel cell electric vehicles.

The EU’s REFLEX project is aimed at developing an innovative renewable energies storage solution, the “Smart Energy Hub,” based on reversible Solid Oxide Cell (rSOC) technology, that is to say, able to operate either in electrolysis mode as a solid oxide electrolysis cell (SOEC) to store excess electricity to produce H2 or in fuel cell mode as a solid oxide fuel cell (SOFC) when energy needs exceed local production, to produce electricity and heat again from H2 or any other fuel locally available (the REFLEX project is discussed in more detail in part one of this FAQ series, “Fuel Cell Technologies and Operating Characteristics“)

mPower GmbH offers SOFC/SOEC stack modules ranging from 5kW to 50kW power output. Integrating mPower’s SOFC/SOEC stack modules into systems requires well-defined electrical connections and gas interfaces. For this, a special module, which includes thermal isolation, current collector, temperature sensors, voltage sensing, etc. is often required.

Fraunhofer IKTS has developed and evaluated various stack modules for different system sizes and power ranges. Based on its long-term experience, a reliable and cost-effective solution can be designed and implemented, starting from single-stack integration and ending with modules, including multiple stacks. Fraunhofer IKTS offers customized stack integration even in case of challenging requirements, and together with mPower, it builds a bridge to novel customized solutions.

As reviewed in part one of this FAQ series, there’s a wide range of fuel cell technologies, each with its own set of features and benefits. Part two has explored the use of various types of fuel cells in stationary power applications. In part three, the growing use of fuel cells in transportation applications, including heavy-duty buses, trucks, trains, planes, and ships, will be discussed.

References

A compact DC distribution solution for easy connection to green power sources, ABB

Ballard Signs ESAs for Fuel Cell Stacks to Support Backup Power Systems at German Radio Towers, Ballard Power Systems

EU’s REFLEX project – Reversible solid oxide Electrolyzer and Fuel cell for optimized Local Energy miX, REFLEX

Plug Power announces commercial launch of Gensure HP fuel cell platform, Plug Power

Leave a Reply