Kevin Parmenter, Director, Applications Engineering, Taiwan Semiconductor, US

Transient protection is common in nearly all electronic circuits. Self-contained automotive electronics systems present a unique challenge requiring a different type of transient voltage suppressor (TVS)

Almost all electronics systems need to be protected from transients and surges. TVS devices are often used to ensure the voltage overshoots don’t exceed prescribed levels. In particular, TVS devices protect against fast high voltage transients induced by lightning strikes and other external voltage disturbances.

Automotive manufacturers have the added challenge of protecting systems from internally induced, excessively high energy transients. This so-called “load dump” condition requires devices capable of safely dissipating this energy to prevent damage to downstream electronic systems. Designers need to choose protection devices that can meet a whole range of standard specifications and various automotive OEM requirements for a wide variety of applications, including trucks and buses, heavy equipment, construction equipment, electric vehicles (EVs), hybrid electric vehicles (HEVs) and many other vehicles of various types and sizes.

The load dump condition

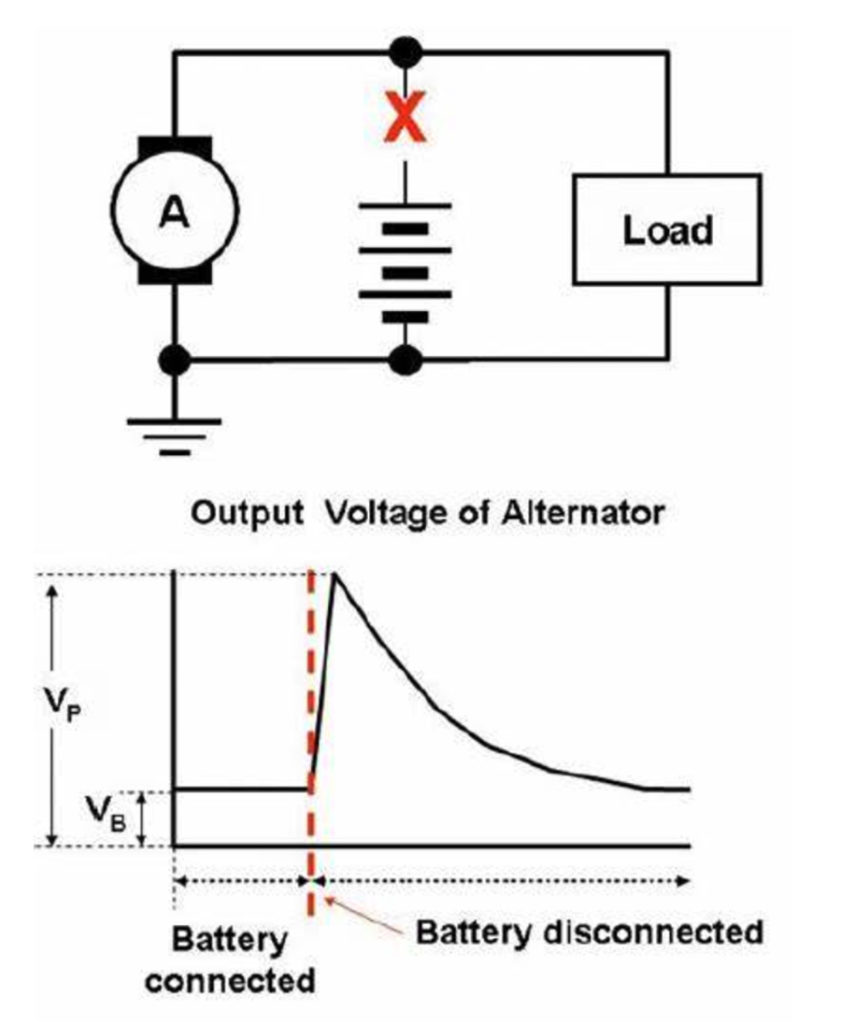

The load dump condition in the vehicle is caused when large loads are applied and removed, such as when a battery is repeatedly connected and disconnected from the alternator (Figure 2). In the worst case, when the battery is fully discharged, this transient overshoot voltage can reach over 100 volts with a very low source impedance and duration of 10s to 100s of milliseconds. If undamped, these transients will undoubtedly result in severe damage to downstream electronic systems in the vehicle.

In a typical 12-volt automotive system, this type of load dump situation is not uncommon. It can arise from corroded or loose battery cables, for example, becoming continually connected and disconnected during the shock and vibration of driving. Jump starting can also cause overvoltage conditions to occur due to transient loading as the cables are connected and disconnected while the vehicle is running. Overshoot and undershoot are not uncommon with any power electronics system; when a transient load is applied and removed, the response time to return to closed-loop control will depend on the feedback loop response of the system. The difference in an automotive system is the amount of energy available during this recovery time can be extremely destructive if not clamped.

Automotive requirements for TVS devices

Makers of OEM automotive electronic systems, as well as aftermarket systems, must consider the presence of less-than-desirable electrical conditions that they will be using for primary power. Additionally, any electrification of transportation systems will have similar use-case conditions, which must be protected against. Figure 3 provides an overview of the most common fault conditions and resulting waveforms present in the automotive electrical system environment.

The “closer in” the electrical system is to the battery, alternator, and fuse block (wiring distribution systems), the higher the magnitude of the transient condition. The solution to these conditions that are present in the vehicle systems are semiconductor TVS devices. Transient voltage suppressor devices are essentially specialized Zener diodes optimized to clamp voltages. However, it’s not used for regulation, as with a regular Zener diode, but is designed to convert transient electrical energy to transient thermal energy. TVS devices are often used to ensure that voltage overshoots do not exceed prescribed levels. Also important is the application of TVS devices to protect against fast, high-voltage transients induced by lightning strikes and other external voltage disturbances.

Figure 4 shows a typical TVS application. During a transient or surge event, a TVS device will clamp the voltage to a safe level that the rest of the electrical system can safely deal with while also shunting the energy long enough to current-limit the source or, in some cases clamping until an electronic circuit breaker or fuse can open, to prevent further damage. Load dump TVS devices can withstand very high peak power – up to 6.6 KW – making them essential for automotive load dump applications.

Automotive protection standards and company-specific requirements

Often the most well-intended specifications, though well thought out, cannot meet the best estimates for energy levels and peak voltages of transients and surges. To complicate matters, electronic systems are getting increasingly sensitive as process geometries decrease and operating voltages are reduced. Thus, any excursion beyond the datasheet maximum operating specifications is more likely than ever to result in component or module failure.

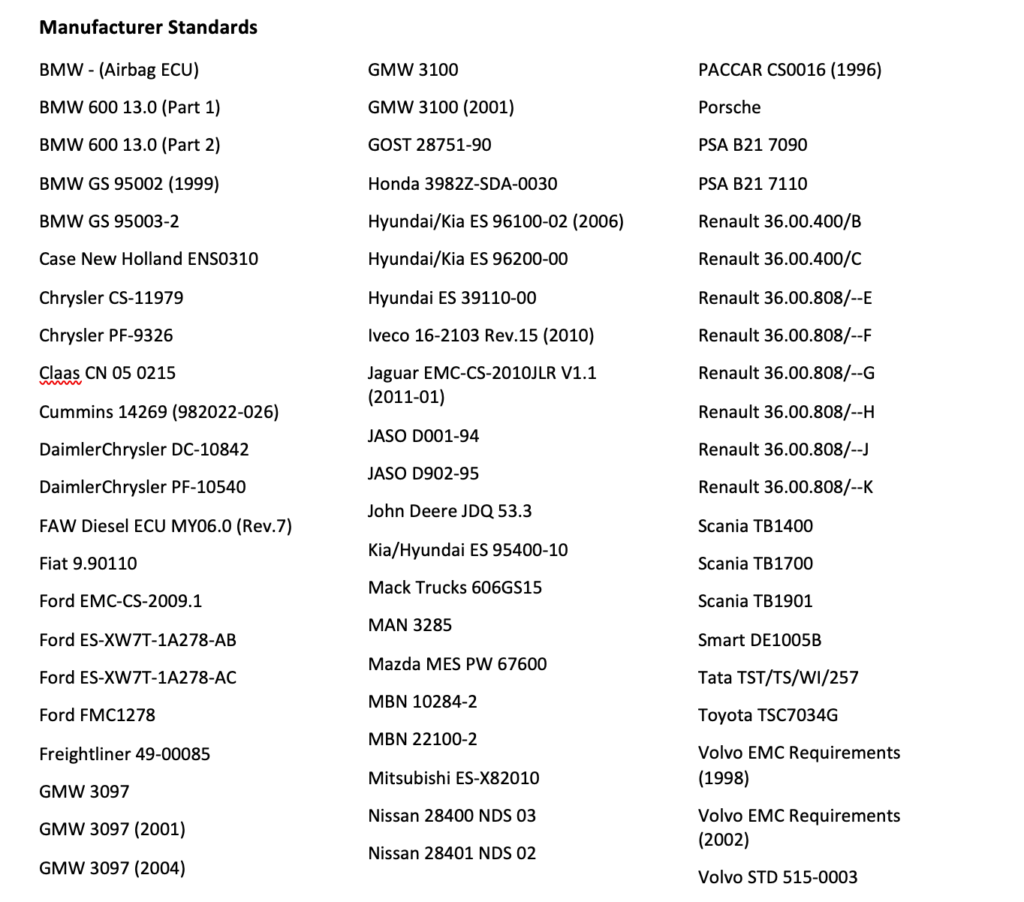

Many automotive standards have been written on testing for these various fault conditions depending on the region, the specific OEM, and the application use case. Among the many modern automotive and transportation/equipment applications that adhere to protection specifications are marine, truck, bus, EV, HEV, aircraft, military, heavy-construction equipment, ATV, and others.

Working closely with a TVS device supplier, the electronics designer can speed the component selection process for a wide range of automotive load dump applications. As a top manufacturer of TVS devices, Taiwan Semiconductor has invested in the necessary test equipment to program the tester for simulation to the specification. As a result, when we receive customer requests for testing to various specifications and for all forms of vehicles, we can quickly recommend a solution to meet the standard. Figure 5 is an example of a typical test.

There are a plethora of automotive-related specifications and test conditions for TVS device applications. The lists in Table 1 and Table 2 are not comprehensive or complete but are representative of the challenges TVS manufacturers must address to comply with customer requirements.

Conclusion

TVS applications in automotive electrical systems are exposed to transients and surges with more electronic system content vulnerable to load dump conditions. These require TVS devices capable of shunting high-energy transients safely away from electronic circuits, such as when the vehicle alternator is disconnected from the battery. In addition to numerous standards addressing this condition, many manufacturers of vehicles ranging from cars to heavy construction equipment have created their specifications. To serve this application, the TVS manufacturer must be able to test and certify the performance of their devices to meet the specific manufacturers’ requirements.

Leave a Reply