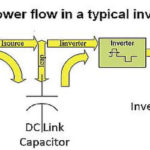

SABIC introduced its new 5-micron ELCRES HTV150 dielectric film for high-temperature, high-voltage, professional-grade capacitor applications, such as traction inverters for hybrid, plug-in hybrid, and battery electric vehicles (xEV). This new film, featuring high-heat performance up to 150°C, surpasses the temperature and voltage capabilities of incumbent products. ELCRES HTV150 film can help support the transition from conventional semiconductors based on silicon (Si) to next-generation, wide-band-gap technologies based on silicon carbide (SiC), improving the efficiency of inverter modules.

SABIC introduced its new 5-micron ELCRES HTV150 dielectric film for high-temperature, high-voltage, professional-grade capacitor applications, such as traction inverters for hybrid, plug-in hybrid, and battery electric vehicles (xEV). This new film, featuring high-heat performance up to 150°C, surpasses the temperature and voltage capabilities of incumbent products. ELCRES HTV150 film can help support the transition from conventional semiconductors based on silicon (Si) to next-generation, wide-band-gap technologies based on silicon carbide (SiC), improving the efficiency of inverter modules.

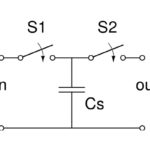

New ELCRES HTV150 dielectric film can support the design of high-voltage, high-temperature DC-link power capacitors that can store large amounts of electrical energy for long periods without significant leakage of current or loss of charge. This technology offers potential advantages for capacitor applications, including excellent dielectric and insulative properties, as well as a low loss at the high frequencies and high temperatures at which wide-band-gap semiconductors operate.

The new ELCRES HTV150 film offers high reliability that is critical for next-generation xEV. Based on internal testing, the film demonstrated a lifespan of 2,000 hours at 500V and 150°C. Furthermore, it is self-healing in the event of a breakdown caused by excessive voltage. This combination of high voltage stability at high temperatures, low dielectric loss at high frequency, and ability to self-heal to avoid catastrophic failure differentiates ELCRES HTV150 film from traditional capacitor films.

With an operating temperature range of -40°C to 150°C and high voltage performance, ELCRES HTV150 dielectric film is an excellent candidate for demanding applications, such as power capacitors for the latest EV traction inverters and onboard chargers. The film can also be used for power capacitors in mass transportation, renewable energy, aerospace, and motor drives and controls.

SABIC’s ELCRES HTV150 dielectric film can be used in industry-standard metallization, capacitor winding, and flattening processes. It has been validated on existing equipment and with various metalized electrodes, including flat and tapered metalized designs as well as patterned electrodes.

With this latest addition to its growing dielectric film portfolio, which includes UTF120 film in four gauges, SABIC is demonstrating its continued commitment to deliver innovative material and film technologies to power electronics to address increasingly stringent customers and industry requirements. SABIC will continue to develop thinner-gauge films to meet requirements for different voltages and higher energy density.

Leave a Reply