One facet of EV ownership: Thinking of your daily commute power consumption as equivalent to the sunlight hitting 20 ft2 of your lawn.

Rudye McGlothlin, Silicon Labs

Earlier this year I took my first step into the EV future by buying a plug-in hybrid electric vehicle (PHEV) – a Chevrolet Volt. A unique car in the hybrid space, the Volt has a relatively large battery, rated for 18.4 kWh. Competing PHEVs available in my region and at a similar price have batteries half the size or smaller. This battery capacity allows the Volt to run as a pure EV for more than 60

miles with the internal combustion engine never starting up.

This battery performance turns out to be perfect for my commute. My commute is about 18 miles each way. I am able to charge at my office, drive home, return the next morning, and still have a good bit of charge on the battery for driving to lunch or for any errands I need to make on the way.

I don’t believe my situation is atypical, and the Volt satisfies my daily commuting needs perfectly. It is a shame that the model isn’t continuing in Chevrolet’s line-up.

Since driving the Volt, I’ve been surprised about how my thinking has changed about PHEVs. There’s no longer any point in monitoring my progress in miles-per-gallon. Instead, I’ve recognized that my home-and-back energy usage is approximately 9 kWh. However, recently my usage has reduced as schools have closed for the summer, and traffic has become less congested.

9 kWh is the amount of charge I need daily. It puts my energy usage in a much different context than my commute using a conventional car powered by an internal combustion engine. I have access to a Level 2 charger at the office, which is convenient for charging during the workday. It takes about three hours for the daily charge. If I must charge at home, where I only have a Level 1 charger, the Volt must be connected overnight. Energy becomes time.

Energy comparisons have also become more straightforward. My daily commute is about 20% of our household energy usage. According to the solar energy potential map at the US Dept. of Energy website (energy.gov), approximately 20 ft2 of my lawn receives enough energy from sunlight in a day to power my commute. In broader terms of scale, my drive is about 7 nano-percent of the daily electricity production of my home state, Texas. It is the energy available from 2,300 AA alkaline batteries.

Battery range and charging speed are two of the biggest influences in EV market demand right now. Every driver must examine their habits and needs to decide whether they are susceptible to the ailment of “range anxiety.” Why don’t internal combustion engine drivers suffer from range anxiety? The answer is, of course, because the recharge stations for that power source are ubiquitous, and the process of filling the tank rarely takes more than 10 minutes. Thus, charging speed and availability are a preventative for the range anxiety ailment.

Technological innovations are in development that could speed charging and mitigate range anxiety. Some of these innovations are in areas like improved battery chemistry to boost power density or advanced charge/discharge algorithms that optimize the two active states of the battery.

Though I’m not regularly exposed to the engineering and discovery that happens in battery technology, I am exposed to emerging innovations in the semiconductor industry.

EV battery pack voltages and capacity are rising. Complex electronics are being developed for efficient maintenance, charging and use in the drivetrain. These developments depend on precise and accurate measurements of the battery pack voltages, currents, and temperature. The measurements must take place on high-voltage rails that have the potential of destroying the sensitive monitoring electronics.

The battery monitoring agent is one node that reports to the car’s central computer, providing important feedback to the operator. By providing up-to-date, accurate information about the state of the battery, the driver can anticipate the travel distance available with the energy remaining. Being able to make that prediction with confidence is a key part of eliminating range anxiety.

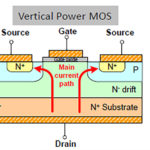

To be effective, that communication channel must be protected. On one side, the battery sits at 400 V, and in the future, it will sit at 800 V or higher. The other side has noisy switching, possibly coupling onto the bus, that would interfere with the sensitive measurements of the battery cells.

Noise and high voltage are common threads through the battery system. So, measurement components, analog-to-digital converters and specialized battery gauge ICs must be isolated when they connect across power domains. This isolation allows a lower-voltage control unit to measure the high-voltage system. Likewise, the communications bus must be isolated from the battery control module to reduce the effect of the overall EV system noise coupling into the battery cell measurements.

Modern CMOS-based isolation technologies have been key for facilitating this isolation in EVs. Modern isolators, manufactured in standard semiconductor facilities, enable more integration than is possible with traditional optocoupler isolation. More measurement functions, and even some calculation or control, can be included with the necessary isolation feature than before. Additionally, important parameters like transient noise immunity, signal propagation delay, power requirements, and product lifetimes improve to the level necessary for EV applications. The Si86xx digital isolators and Si8920 analog isolators from Silicon Labs are examples of modern isolators useful in EV battery applications.

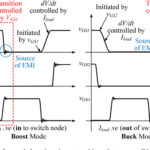

The on-board charger (OBC) is another system in electric and plug-in hybrid electric vehicles that greatly benefits from semiconductor innovations. This is one area where my Volt feels behind the curve with respect to current technology. The OBC in the Volt operates at 3.3 kW and is the component setting the charge times. Advanced architectures, paired with advanced switch technologies, have pushed OBC capabilities up steadily. Newer EV designs come equipped with onboard chargers that are 2x to 4x the capability of the OBC on my Volt. That directly corresponds to faster charging of larger batteries. Again, this development will help offset some consumer range anxiety with the promise of a faster recharge.

OBC power output levels directly depend on the efficiency of the power transfer architecture. Low efficiency means larger transformers and heatsinks, increasing the overall size and weight of the charger. New wide-bandgap switch technologies create an opportunity to massively shrink the OBC and boost power density. These transistors switch at faster rates, which reduces the size of the magnetics, and they have lower power losses, reducing the need for bulky thermal management.

State-of-the-art power switches require innovative isolated-gate drive technology to function. Robust isolation enables the switches to go through the entire power conversion commutation that includes connection to a high-voltage bus. A fast gate drive, with considerable rejection of transient noise, is a requirement for taking advantage of the rapid-switching capabilities of wide-bandgap transistors. For example, the Silicon Labs Si827x and Si8261 isolated gate drivers enable high-power OBCs for the latest fast-charging EVs and PHEVs.

My Volt has given me a new prospective on my energy use and how it relates to transportation. It is also exposing me to some of the concerns in the broader EV market and highlights how innovation from semiconductor suppliers can address them. More efficient use of the battery capacity depends on clean sensing and communication with computing and control resources. Both depend on the latest isolation technology available. Charging power, directly related to the time needed to charge, is steadily rising due to availability of new transistor switches and the isolated gate drivers needed to control them. All these power semiconductor innovations, as well as the automobile designs they enable, make me excited and optimistic about the future of EVs and PHEVs.

Leave a Reply