It pays to know when the use of a single fuse is less hazardous than fusing both hot and neutral wires.

David Norton | TDK-Lambda Americas

For many years ac-dc power supplies for the medical market have been safety certified to the IEC 60601-1 medical standard and to the industrial IEC 60950-1 /IEC 62368-1 standards. Dual certification reduces the number of individual model numbers manufacturers must produce and stock.

A point to note is that two ac input fuses are needed in many medical applications, one in the Line side and one in the Neutral side. Dual fusing is necessary to guarantee full protection if the polarity of the Line and Neutral wiring to the power supply should be reversed. This condition might arise due to a wiring error at the building’s ac socket or in the wiring feeding the power supply.

A point to note is that two ac input fuses are needed in many medical applications, one in the Line side and one in the Neutral side. Dual fusing is necessary to guarantee full protection if the polarity of the Line and Neutral wiring to the power supply should be reversed. This condition might arise due to a wiring error at the building’s ac socket or in the wiring feeding the power supply.

Nevertheless, supply manufacturers such as TDK-Lambda now offer a single (Line) fuse option on new medical/industrial power supplies. Here is the explanation why:

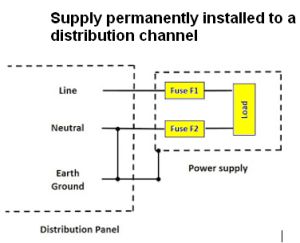

If an industrial system is consuming more current than a regular ac socket can support, it would have to be permanently connected to a distribution panel or building wiring. This task is normally carried out by a professional electrician, who would be aware of the potential dangers of a polarity reversal.

In the event of an over-current fault in the power supply or fuse aging, there is a 50% chance that either the Line or Neutral fuse would open. If the Neutral fuse was to open, a service technician may believe that there is no ac power applied to the power supply. Inadvertent contact with the Line while touching the earth ground would result in an electrical shock. This is even more likely if the power supply in question is of an open frame type construction.

To avoid this possibility, the NEC, CEC, IEE Wiring Regulations and IEC 364 specifically prohibit fusing in the Neutral in this type of equipment. To comply, a single-fuse power supply must be selected. The candidates are typically industrial (single fuse) or medical/industrial power supplies with a single-fuse option.

This scenario brings up the question of whether there are cases where an external fuse should go in the neutral connection of an industrial DIN rail power supply. DIN rail power supplies are rarely certified to medical safety standards. Usually they only have a single input fuse.

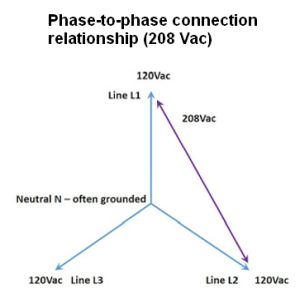

Consider the case where the application is a power supply operating phase-to-phase from a three-phase WYE configuration in North America. Connecting phase-to-phase enables the equipment to be supplied with 208-Vac which draws less input current than using 115 Vac. This configuration allows the use of smaller wire gauges and connectors which saves money and are easier to install.

Consider the case where the application is a power supply operating phase-to-phase from a three-phase WYE configuration in North America. Connecting phase-to-phase enables the equipment to be supplied with 208-Vac which draws less input current than using 115 Vac. This configuration allows the use of smaller wire gauges and connectors which saves money and are easier to install.

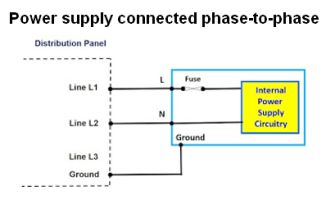

In the UL safety report Conditions of Acceptability, or Technical Considerations section, reference is made to all testing being performed on a protected branch circuit rated for 20 A; this section also lists the items that a user should consider before applying power to the unit.

If a short or overload inside the power supply happens across the Line-and-Neutral or Line-and-Ground, an internal fuse will open. If the short happens from Neutral-to-Ground, the fuse or breaker at the distribution panel will open.

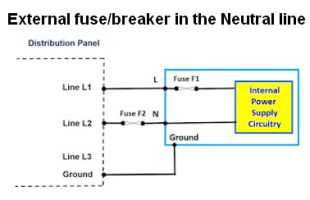

If, however, the equipment connection to the building installation wiring is made via a non-industrial plug and socket, then an external fuse or breaker must be added in the Neutral line. This applies to input voltages of less than 240 Vac +10%.

If, however, the equipment connection to the building installation wiring is made via a non-industrial plug and socket, then an external fuse or breaker must be added in the Neutral line. This applies to input voltages of less than 240 Vac +10%.

It is best to always have your equipment installed by a qualified electrician and checked by a safety engineer for compliance to the relevant building and electrical codes!

Leave a Reply