Haptics capabilities are embedded in smartphones and game controllers, and their use is expanding into robotic controls, automobile consoles, and more; the physical actuator and its driver are the key hardware elements.

Part 1 of this article examined actuators for haptics functions. This section examines an equally important part of the haptics hardware: the actuator drivers, which provide the needed voltage, current, and dynamics for the actuator.

LRA & ERM drivers

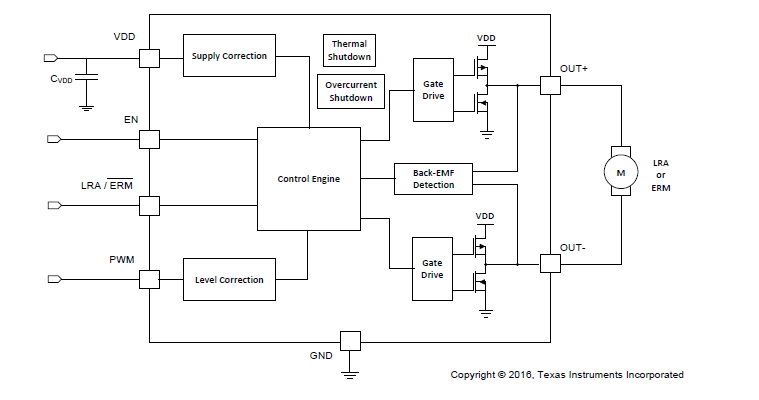

Despite the fundamental differences in construction and operation between the LRA and ERM actuators, their drive requirements are similar enough that both can be supported by the same circuit, usually as an IC. One such device is the DRV2603 from Texas Instruments, designed for low latency, high efficiency, and needed drive strength for LRA and ERM actuators.

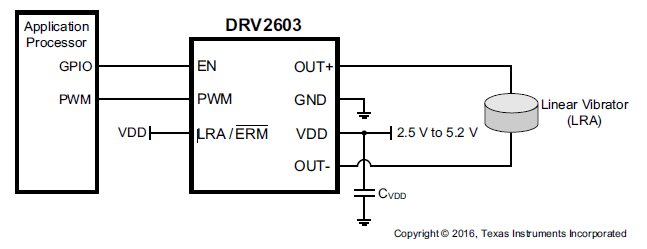

The apparent internal complexity of the DRV2603 (Figure 1) is not reflected in its almost trivial external connections to either the LRA or ERM devices and the supporting microcontroller (Figure 2). The DRV2603 output is controlled using a pulse-width modulated (PWM) input, and the PWM duty cycle determines the amplitude of the output waveform. Advanced haptic patterns and sequences such as clicks, bumps, pulses, ramps, and many more can be created, varying the duty cycle. (If a PWM port is not available on the microcontroller, the DRV2603 PWM pin can be controlled with a general-purpose input/output (GPIO) pin, but this limits the DRV2603 to functioning only as an ON-OFF driver.

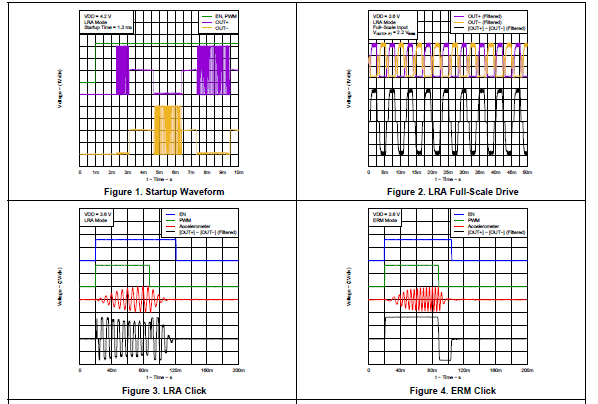

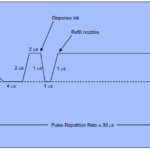

The DRV2603 also incorporates a feature that enhances its performance, specifically with the LRA. An LRA has a relatively narrow resonant-frequency bandwidth of about 10 Hz or less, and this frequency will vary with the specific LRA make and model, as well as unit-to-unit shifts due to production variations and the physical mounting of the LRA in the end application. To minimize inefficiency due to driving at an off-resonant frequency, the DRV2603 includes auto-resonance tracking, automatically detecting and tracking the LRA resonant frequency in real time. As a result, any input-PWM frequency within the input range of 10 kHz to 250 kHz will automatically produce the correct resonant output frequency (Figure 3) shows some of the drive waveforms and voltages generated by the DRV2603 for both LRA and ERM actuators.

Piezo drivers

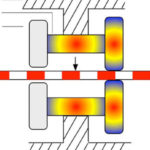

The piezo-actuator driver is very different from the LRA/ERM driver. The high voltage needed to deform the piezo actuator depends on the design and fabrication of the piezo device and typically ranges from 50 VPP (for 16 to 24 layers) to 150 VPP (4 layers). The drive current is lower with higher voltages and a lower number of layers since the piezo actuator’s capacitance is lower.

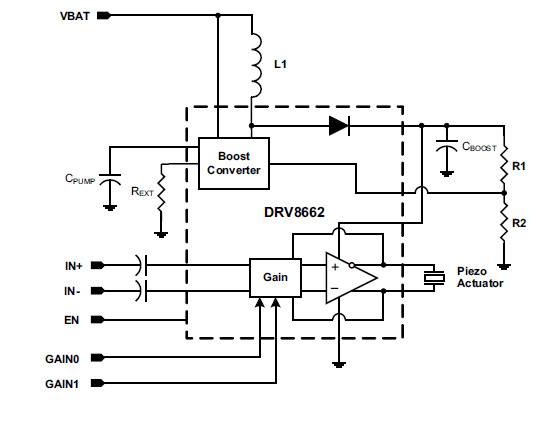

Again, Texas Instruments offers a piezo-specific haptics-actuator driver IC. Their DRV8662 is a single-chip piezo haptic driver with an integrated 105-V boost switch, integrated power diode, and integrated fully differential amplifier, Figure 4. This device can drive both high-voltage and low-voltage piezo haptic actuators. A typical start-up time of 1.5 milliseconds makes the DRV8662 suitable for fast haptic responses. It can drive up to 100 nF loads at 200 VPP, 150 nF at 150 VPP, 330 nF at 100 VPP, and up to 680 nF at 50 VPP, all at 300 Hz.

Other vendors have also recognized the business opportunities for an improved piezo driver, which minimizes design-in and connectivity issues, as the piezo actuator has distinct advantages compared to LRA and ERM units. For example, the BOS1901 Piezo Haptic Driver from Boréas Technologies is a single-chip piezo-actuator driver with high-efficiency energy recovery based on their patented CapDrive™ technology. It can drive 100 nF actuators with up to 190 Vpp waveforms (at 300 Hz) while operating from a 3 V to 5.5 V supply voltage using only 350 mW power and up to 820 nF at lower voltages. Only seven external passive discrete components are required, and the typical start-up time is less than 300 µsec, so it allows the speed of piezo devices to be used and not squandered.

Conclusion

Haptics functionality is being adopted and embedded in many applications beyond smartphones and game controllers. Their use in even those two applications is also expanding in function and capability. Designers can choose among LRA, ERM, and piezo-based actuators. The first two types are mechanically very different but have overlapping drive needs. At the same time, the third is a very different component with respect to operating principles, construction, capabilities, and driver needs. A complete haptics system requires careful matching between the hardware driver and actuator. In contrast, the software that controls the hardware driver is a critical part of the complete subsystem with its issues, development tools, and capabilities.

Related EE World Online Content

- FAQ: Piezoelectric motors, Part 1: actuators

- FAQ: Piezoelectric motors, Part 2: drive circuits

- World’s First Mechanically Customizable Haptics in TacHammer Developer Kit

- Haptics driver IC powers eccentric rotating mass, linear resonant actuator motors

- The Tinker’s Toolbox – Eric Siegel of TI on Haptics Feedback in Touch-Enabled Devices

- Desktop Development Kit enables textures/haptic effects defined by software

- Flexible roll-to-roll actuators work like piezoelectrics, include high-voltage drivers

- Designing and manufacturing haptic sensors for robotic surgery platforms

- FAQ: Piezoelectric motors, Part 1: actuators

- How Soundscapes And Vibrations Are Helping Blind People See The World

- Engineers Developing Advanced Robotic Systems That Will Become Surgeon’s Right Hand

References

- Boréas Technologies, “Here’s Why Piezo Should Be The Most Used Haptic Technology”

- Boréas Technologies, “BOS1901 Piezo Haptic Driver”

- Michigan State University, Michael Greene, ECE480: Design Team 4 Application Note, “Haptic Feedback

- Technology”

- com/Mide Technology, “Haptic Actuators: Comparing Piezo to ERM and LRA”

- Precision Microdrives, “AB-020 : Understanding Linear Resonant Actuator Characteristics”

- Precision Microdrives, “Eccentric Rotating Mass Vibration Motors – ERMs”

- Precision Microdrives, “AB-028 : Vibration Motor Comparison Guide”

- Sparkfun Electronics, “Haptic Motor Driver Hook-Up Guide”

- Texas Instruments, SSZB151, “Haptics Solutions for ERM and LRA Actuators”

- Texas Instruments, SLYT483, “High-definition haptics: Feel the difference!”

- Texas Instruments. DRV2603 Data Sheet

- Texas Instruments, DRV8862 Data Sheet

Leave a Reply