TDK Corporation has introduced a thin pattern coil to support the wireless charging of next-generation mobile devices. Mass production began in May 2022.

The WCT38466-N0E0SST101 product was developed without employing conventional lithographic exposure/etching techniques. Developed by Achilles Corporation, TDK’s game-changing process technology was leveraged, combined with plating technology that uses the nano dispersion of the organic compound polypyrrole.

The WCT38466-N0E0SST101 product was developed without employing conventional lithographic exposure/etching techniques. Developed by Achilles Corporation, TDK’s game-changing process technology was leveraged, combined with plating technology that uses the nano dispersion of the organic compound polypyrrole.

Although wireless charging coils have typically been produced by winding wires, this new approach has made it possible to manufacture them using a thick copper pattern on a thin film.

This, along with the application of TDK’s proprietary magnetic materials has enabled coil thickness reduction down to 0.76 mm – which is approximately one-fifth of the thickness of traditional 3.8 mm diameter wound wire coils.

Furthermore, the use of TDK’s original optimal coil shape pattern means that the new coils cover a larger charging area, resulting in greater user convenience.

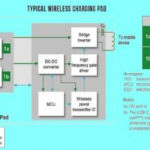

The wireless transfer of power to mobile devices, such as smartphones, has considerable appeal. Uptake of demand for wireless charging is being seen in home, office, retail, and automotive environments. With their dramatically thinner diameters, the TDK coils, compliant with the Wireless Power Consortium’s widely-adopted Qi standard, will open up new opportunities for wireless charging deployment.

In addition, while it was previously necessary for three coils to be incorporated into wireless charging systems, now only one coil will be required, thereby enabling system miniaturization.

Applications

•Wireless charging of mobile devices (smartphones)

Features:

•A thickness of 0.76 mm

•A coil that enables a larger charging area

•Compliant with the Qi wireless charging standard

thank you for the information