A clever way to lay out power modules

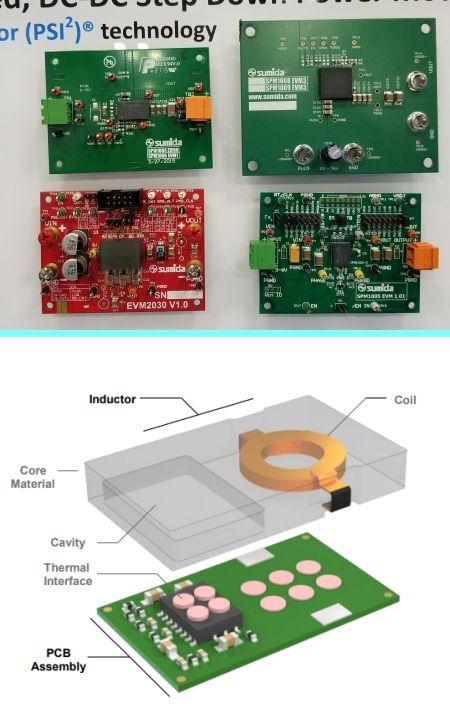

As you’d expect, there were power modules galore in evidence at APEC. These examples from Sumida America Components Inc. in Schaumburg, Ill. were noteworthy because of their clever way of getting a high energy density. Basically, most of the components lie inside the power inductor which, Sumida says, provide several advantages. The inductors themselves can use larger-gauge wire and coil diameters to minimize power loss. The inductor body encases the switching components which provides EM shielding and cuts EMI. The inductor body acts as a heat sink to help reduce module surface temperature by up to 11.5°C compared to designs with internal inductors. The boards visible here are demos for dc-dc step-down modules ranging in capacity from 2 to 30 A.

As you’d expect, there were power modules galore in evidence at APEC. These examples from Sumida America Components Inc. in Schaumburg, Ill. were noteworthy because of their clever way of getting a high energy density. Basically, most of the components lie inside the power inductor which, Sumida says, provide several advantages. The inductors themselves can use larger-gauge wire and coil diameters to minimize power loss. The inductor body encases the switching components which provides EM shielding and cuts EMI. The inductor body acts as a heat sink to help reduce module surface temperature by up to 11.5°C compared to designs with internal inductors. The boards visible here are demos for dc-dc step-down modules ranging in capacity from 2 to 30 A.

NEXT PAGE: Capacitors in the limelight: Operation at high temperatures, better supercap chemistries

Leave a Reply