Peltier modules or thermoelectric coolers (TEC) have grown in popularity and found uses in many applications due their reliable solid-state construction and precise temperature control. They operate by transferring heat from one side of the module to the other when electrical power is applied. Although all Peltier devices are constructed using the same general structure, enhancements can be made to increase performance and cycle life.

Peltier modules or thermoelectric coolers (TEC) have grown in popularity and found uses in many applications due their reliable solid-state construction and precise temperature control. They operate by transferring heat from one side of the module to the other when electrical power is applied. Although all Peltier devices are constructed using the same general structure, enhancements can be made to increase performance and cycle life.

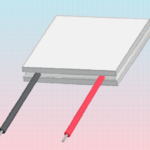

CUI Devices’ arcTEC™ structure is one such advanced construction technique that utilizes three enhancements (thermally conductive resin, high temperature solder, and larger P/N elements) to greatly improve performance, reliability, and lifespan.

The CUI Insights™ blog post, “arcTEC™ Structure – Improved Performance and Longer Life in Peltier Modules” dives into these improvements in more detail, while providing an overview of Peltier module technology.

Hi, I’m interested in the elements or factors that influence Peltier module design.

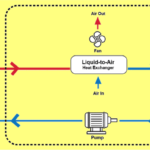

It seems to me that the biggest factor is the heat transfer management, which looking at the standard design seems a bit lacking.

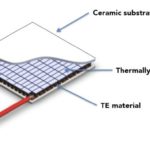

Am I right to assume that the ceramic used is a thermally conductive type?

Bruce, I spoke with some of our engineers about your question. This was their response:

Some of the factors that influence Peltier module design are size and efficiency of semiconductor pellets, thermal equilibrium across the device, electrical and mechanical bonds, and operational life optimization. Peltiers are designed to maximize the active heat transfer and temperatures across the device. The ceramic used on Peltiers are designed to maximize both thermal conductivity and equilibrium as well as minimize thermal expansion and provide structure for the module.