Pulsiv emerged from stealth mode, with the announcement of its new power electronics technology. Pulsiv OSMIUM uses a patented method for converting AC to DC that involves charging/discharging a small storage capacitor without the need for a PFC inductor. This unique solution delivers a high power factor, consistently high efficiency, and an ultra-compact system design. Pulsiv OSMIUM technology can be used to improve overall system efficiency, optimize cost and contribute to reducing global energy consumption.

Pulsiv emerged from stealth mode, with the announcement of its new power electronics technology. Pulsiv OSMIUM uses a patented method for converting AC to DC that involves charging/discharging a small storage capacitor without the need for a PFC inductor. This unique solution delivers a high power factor, consistently high efficiency, and an ultra-compact system design. Pulsiv OSMIUM technology can be used to improve overall system efficiency, optimize cost and contribute to reducing global energy consumption.

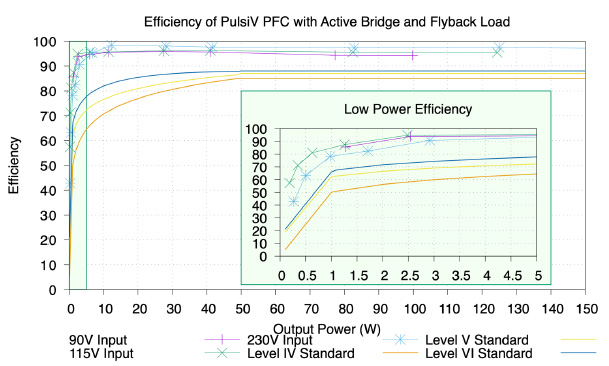

The Pulsiv OSMIUM microcontroller family and supporting components can be combined with commodity flyback DC-DC converters to displace higher-cost LLC solutions. Pulsiv has demonstrated a universal input, single switch 150W flyback power supply design that delivers 97.5% average (99.5% peak) front-end efficiency while maintaining 90% at just 2W. A 240W interleaved flyback is currently being developed and work is underway to showcase reference designs with even higher power capability. Pulsiv OSMIUM microcontrollers (PSV-AD-150 and PSV-AD-250 sampling now) do not directly determine output power and can be used as a platform for any application requiring 1W to 10kW, by adjusting only three system components and connecting a suitable DC/DC converter.

There are so many trends, whether it’s more things going battery power—e-bikes, electric vehicles, scooters— and that means more things need to be charged,” said Mohammed Zaki Ahmed, Chief Strategy Officer, “And with charging, particularly fast charging, one of the limiting factors is having cost-effective electronics to support it because having the latest battery technology is no good unless you can get the energy into it. That becomes more difficult as the faster you want to charge things, the more power you need to get into them. We’ve had lots of conversations recently about companies that want to move too fast battery charging, but they can’t because it’s cost prohibitive.”

Ahmed continues, “The approach we have taken with the ultimatum product is, is effectively based on my background as a communications engineer. Typically in a power supply where you have power factor correction, you will have an inductor in series, and then you’ll have some switching to regulate the current in that inductor, and then you have the follow-on stages as a consequence of that. What we’ve done is we’ve replaced that inductor in series with a capacitor in parallel. And what we provide are effectively two parts, one to charge the capacitor and one to discharge it. Effectively, what we do is look at the incoming grid; we know how much energy is stored in the capacitor. And based on these two factors, the algorithm figures out how to charge the capacitor in the most efficient manner, so that you achieved the highest power factor.”

“The big difference in terms of what we’re doing compared to the series inductor approach is in a series inductor; all your energy has to go through the inductor whereas, with our approach, you’re only storing and supplying energy when the grid can’t supply the energy to your DC to DC converter,” explained Ahmed. “And this difference ends up with a remarkable change in terms of the overall efficiency of the power supply, because inductors you normally design them for a given power level.”

Critical components in a Pulsiv OSMIUM circuit operate at low temperatures to extend their expected operating life, even under convection cooling. By regulating the flow of mains through a charging capacitor, Pulsiv has completely eliminated inrush current, meaning that manufacturers of industrial power supplies and LED lighting products can simplify their designs and reduce the cost of system installation. Finally, Pulsiv OSMIUM technology supports Active Bridge Control, Configurable Hold-Up, X-Cap Discharge, HVDC Output Selection, a Power Consumption Indicator, and Grid Failure Detection. These optional features can be selected as required to meet the needs of different end applications.

Critical components in a Pulsiv OSMIUM circuit operate at low temperatures to extend their expected operating life, even under convection cooling. By regulating the flow of mains through a charging capacitor, Pulsiv has completely eliminated inrush current, meaning that manufacturers of industrial power supplies and LED lighting products can simplify their designs and reduce the cost of system installation. Finally, Pulsiv OSMIUM technology supports Active Bridge Control, Configurable Hold-Up, X-Cap Discharge, HVDC Output Selection, a Power Consumption Indicator, and Grid Failure Detection. These optional features can be selected as required to meet the needs of different end applications.

The PSV-AD-250-DS development system can be used by engineers to evaluate Pulsiv OSMIUM technology and connecting a suitable DC-DC converter will produce a complete power supply prototype. Full reference designs are being made freely available via the Company’s website, to showcase what’s possible when Pulsiv OSMIUM is combined with a carefully selected DC-DC converter. Engineering samples of the Pulsiv OSMIUM microcontrollers will be made available through a network of distribution partners.

Leave a Reply