By Darrel Kingham, CEO, Pulsiv

To comply with tightening regulations aimed at reducing energy consumption and achieving “Net Zero” targets, the global electronics industry must embrace new and innovative methods of designing efficient products that are also economical to manufacture. While GaN and SiC technologies have become a popular choice for enhancing peak efficiency, they have a limited impact during low-power modes where devices tend to operate most of the time. With a growing number of smart devices constantly connected to the internet during standby, poor efficiency at low power represents a significant source of waste.

In this article, we analyze some typical power supply efficiency profiles, how they influence overall efficiency in different usage scenarios, and explore an entirely new approach from Pulsiv that can deliver significant improvements without adding cost.

Why are traditional power supply designs inefficient at low power?

Converting AC to DC involves combining a Boost PFC design and a Flyback or LLC topology. Multiple variations and combinations are available to deliver a high power factor and maximize peak efficiency, but they share a similar performance profile that compromises efficiency more dramatically as the load is reduced.

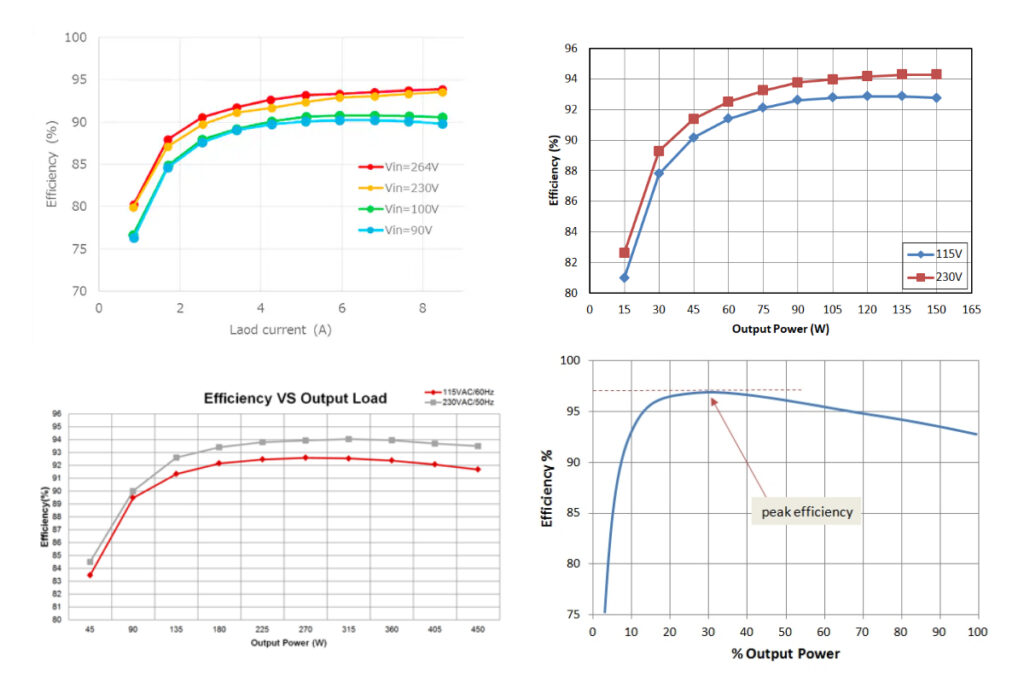

In these graphs (published for commercially available power supply designs), the trend is clear:

- Performance at low load conditions is noticeably reduced as a direct result of losses in the series inductor used for power factor correction

- Maximum efficiency is not usually achieved until full load

- No data is reported below 10 – 20% of the load because the numbers are usually unimpressive

- The efficiency at 115V is lower than 230V, but the profile is similar

How load conditions impact average efficiency

The electricity consumption of a product will vary depending on its typical operation and intended purpose, with most spending a small percentage of the time running at full power. A significant number of devices remain in standby mode, and all internet-connected products continue to perform necessary background tasks such as monitoring or updates even when not in use.

Kitchen appliances, for example, are typically used for relatively short periods of time and remain in standby mode for quick access. In contrast, smart TVs, games consoles, printers, & security cameras provide continuous intelligent monitoring & remote-control features for consumer convenience.

Certain industrial products such as Air Conditioning Units, Factory Equipment, and Motor Drives may have simple on/off control, operate at maximum power when used, or benefit from manual adjustment.

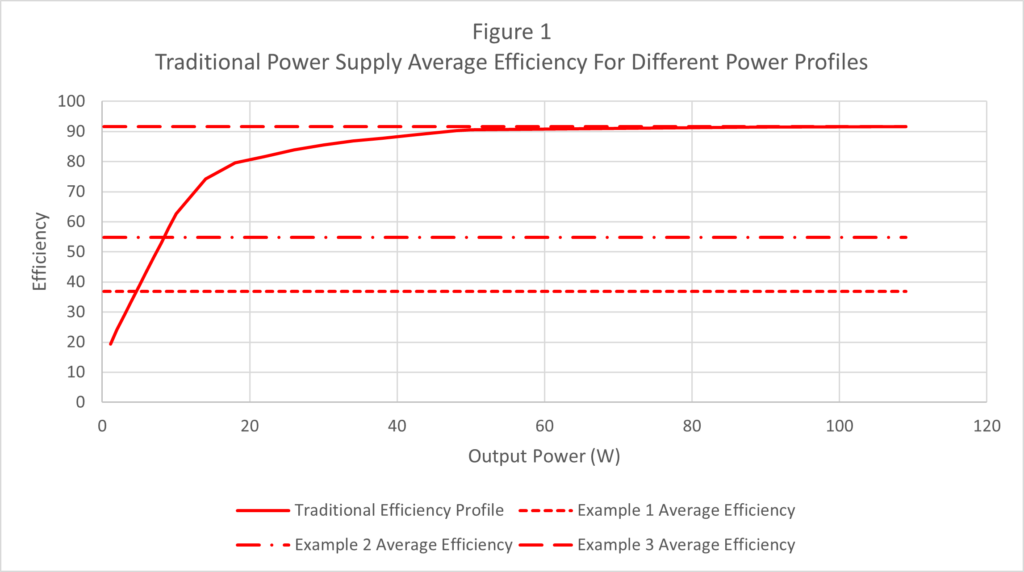

Figure 1 demonstrates the average efficiency of a product using traditional power supply technology, depending on how it behaves during normal operation:

Example 1 shows an average efficiency of just 37% when 80% of the time is spent in standby mode, 10% in low-power mode, and 10% at full power.

Example 2 shows an average efficiency of just 56% when 50% of the time is spent in standby mode, 40% in low-power mode, and 10% at full power.

Example 3 shows an average efficiency of 91% when 100% of the time is spent at full power.

While the peak efficiency of a typical power supply may look impressive, this demonstrates the importance of understanding typical usage and the impact on overall average efficiency.

While GaN and SiC technology can help to improve peak efficiency in premium power supply designs, they do not change the general efficiency profile. It is possible to use multiple power supplies that handle conversion in different operating modes, but this involves added complexity and system cost. Pulsiv OSMIUM offers a new approach that delivers high efficiency at all times and maximizes the power available for meaningful work using a simple and economical design.

The effect of Pulsiv OSMIUM technology

Pulsiv has designed, developed, and patented a new front-end AC-to-DC power conversion method that delivers:

- High flat efficiency with 97.5% average, 99.5% peak, and 90% at just 2W

- 96% power factor

- Universal mains input voltage

- No inrush current

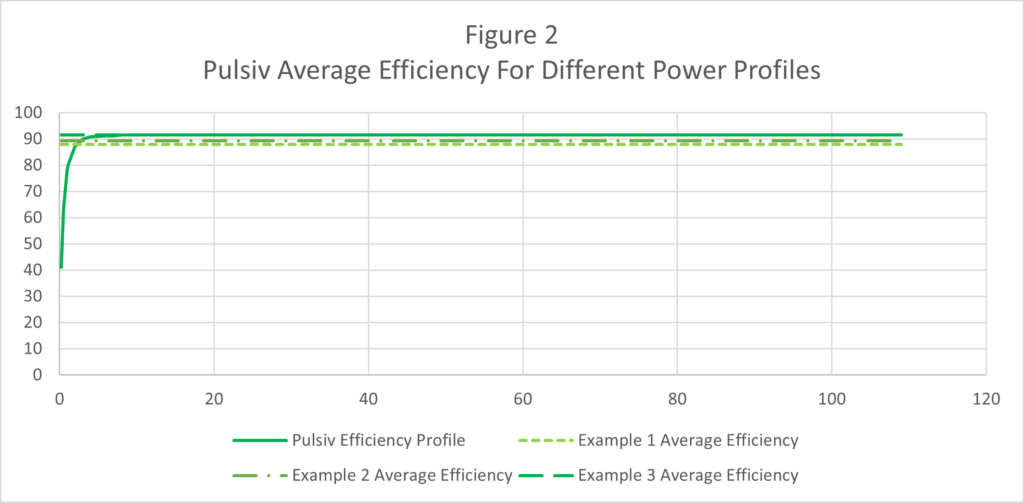

Figure 2 demonstrates a significant improvement in average efficiency when using Pulsiv OSMIUM technology paired with a quasi-resonant flyback. Under the same conditions:

Example 1 shows an average efficiency of 88% compared to the previous 37%

Example 2 shows an average efficiency of 89% compared to the previous 56%

Example 3 shows the same average efficiency of 91% without the complexity of using an LLC.

Many governing bodies, such as The European Commission and the US Department of Energy (DOE), constantly drive manufacturers to improve efficiency and reduce energy consumption by setting minimum standards for different applications. As a result, they face an ongoing design challenge which typically involves adding system complexity, development time, and BoM cost. Engineers can avoid such compromises by combining Pulsiv OSMIUM technology with commodity flybacks to replace conventional LLC designs.

What is Pulsiv OSMIUM technology?

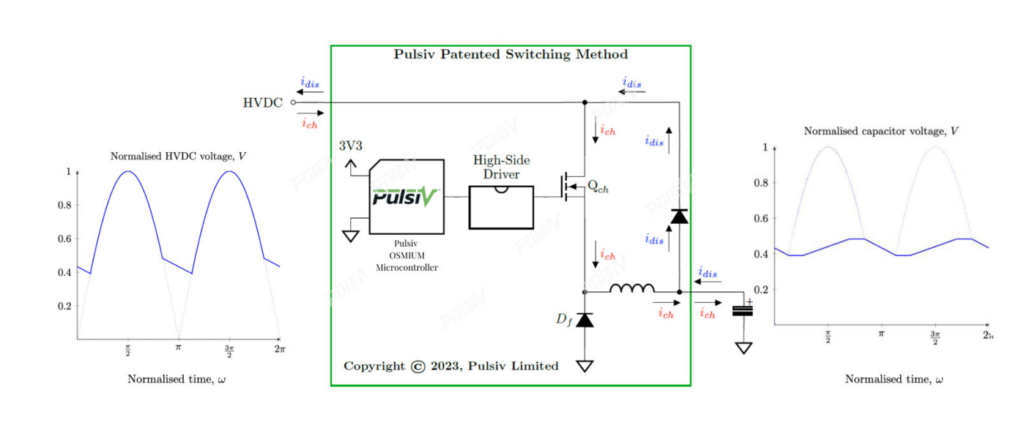

Pulsiv OSMIUM technology uses patented switching techniques to improve efficiency at low loads and therefore increase average efficiency. Significant energy waste reduction is achieved by charging a parallel capacitor which replaces a lossy boost PFC inductor. The Pulsiv OSMIUM microcontroller manages the entire conversion process to ensure that just enough energy is available to ride through a period when the grid cannot support the load. The capacitor is then discharged by a follow-on dc-dc converter through a simple diode. The voltage on the storage capacitor is regulated to 150V or 180V (pin selectable), which means avoiding conventional 400V larger and more expensive capacitors.

About Pulsiv

Founded in 2013 as a spin-out from the University of Plymouth (UK), the company has developed and patented technology to significantly improve efficiency and reduce the energy wasted in power electronics designs used in virtually any mains-powered or battery-charging application.

Leave a Reply