Traction motors are optimized for locomotives, EVs, elevators, and other situations where high torque at start-up and low speed is needed.

The previous part of this article established the context for traction motors. This part looks at traction motors in more detail.

Q: What is the relative position of DC versus AC traction motors?

A: In the early days of electric traction – the first decades of the 20th century – both DC and AC motors were tried. At that time, the technology (admittedly crude by our standards) favored the DC motor as it provided the needed torque characteristic for railway operation and was amenable to control, even if it was not simple to implement. By the 1970s and early 1980s, however, power electronics had progressed to the stage where the 3-phase AC motor had become a serious and more efficient alternative to the DC motor because:

- They are simpler to construct, require no mechanical contacts (brushes) to wear or fail, and are lighter than DC motors for equivalent power.

- Modern electronics allow AC motors to be controlled effectively to improve performance and efficiency. Further, AC motors can be processor controlled with sophisticated algorithms that further improve performance, control adhesion and slippage, and offer many operational advantages.

- They are more robust and easier to maintain than DC motors.

Q: What are the basics of DC motors?

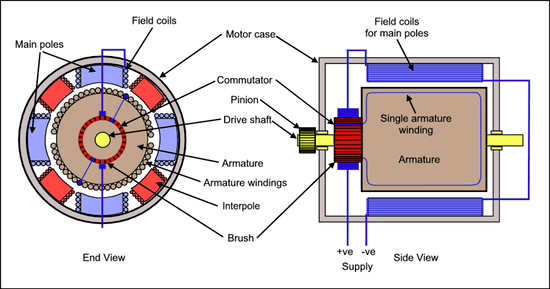

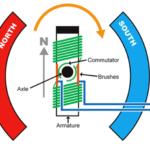

A: The first electric motor was the brushed DC motor; large and small ones are still in use. The brushes (spring-loaded contacts) press against an extension of the armature called the commutator (Figure 1). As the magnetic fields of the stator and commutator fields interact, the commutator rotates, and the brushes “switch” the current direction so the field reverses and thus continues to push the rotor.

The high current results in strong magnetic fields and high starting torque (turning force), so it is well-suited for starting a heavy object like a train. Controlling the speed and torque over a wide range, however, is difficult and was done by manually switching resistors in and out, in both series and parallel, to match the applied current and current to the load, speed, and torque objectives.

In general, most new systems do not use DC brushed traction motors due to control and maintenance issues, and high performance can now be achieved using AC-driven motors.

Q: What about AC-driven motors?

A: There are two types of AC motors: synchronous and asynchronous (induction) motors. The synchronous motor is “encouraged” to rotate by the alternating AC current applied to its windings. The AC motor has no brushes since there is no electrical connection between the armature and the fields, and the armature can be made of steel laminations instead of the large number of windings required in other motors. These features make it more robust and cheaper to build than a DC-based commutator motor.

Q: What are the attributes of the asynchronous AC drive?

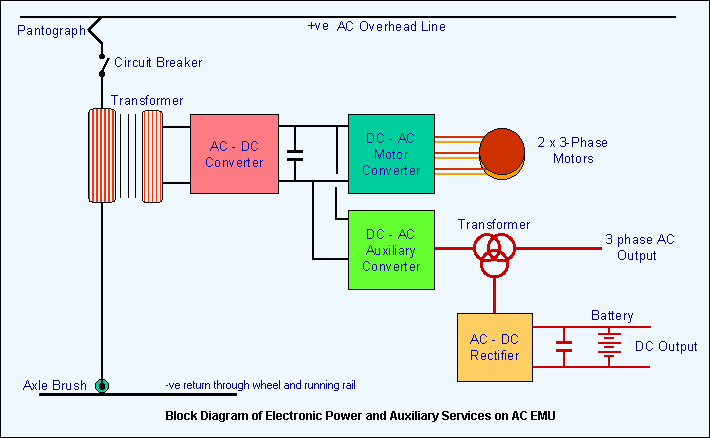

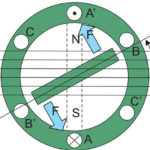

A: Modern electronics, especially the insulated bipolar gate transistor (IGBT), make the asynchronous AC drive practical (Figure 2). The speed of a 3-phase AC motor is determined by the frequency of its supply but, at the same time, the power must be varied to match the load and torque requirements. The 3-phase traction motor is controlled by feeding in three AC currents which interact to cause the machine to turn. The three phases are most easily provided by an inverter that supplies the three variable-voltage, variable-frequency (VVVF) inputs, with the variations of the voltage and frequency electronically controlled and optimized.

Q: Is AC or DC the preferred higher-voltage primary-line power source for traction motors?

A: It depends. For railways, either AC or DC can be used; of course, it must be stepped down and re-converted to the voltage/frequency needed by the traction motor. For many years, AC was preferred since it was much easier to step up/down from the primary power source (generator at the power plant) to the desired voltage for the transmission line. The availability of high-performance solid-state devices such as IGBTs and thyristors, however, makes it possible to effectively step up/down DC, and there are long-transmission line advantages to using DC.

As for cars and their traction motors, the primary source is batteries, of course, so it is a DC-source situation. Again, this must be stepped up/down and transformed to AC for the motors.

The final part of this article examines additional traction-motor issues.

Related content

The brushed DC motor: Still a very viable option, Part 1: Operation

The brushed DC motor: Still a very viable option, Part 2: Applications

Electric locomotives and catenary power systems – Part 1: basic functions

Electric locomotives and catenary power systems – Part 2: power needs

Electric locomotives and catenary power systems – Part 3: power delivery

Electric locomotives and catenary power systems – Part 4: maintenance and corona

Basics of motion-control profiles, Part 1: Context

Basics of motion-control profiles, Part 2: Ramp profiles

Basics of motion-control profiles, Part 3: Implementations

Motor fundamentals and DC motors

SiC gate driver benefits traction inverters for EVs

Discrete 750-V IGBTs optimized for automotive traction inverters

Full SiC power module optimized for electric/hybrid traction motorsports apps

IGBT power modules optimized for EV traction inverters

Magnetic gear tooth sensor IC optimized for traction motor apps

Wide-input-range, high power density dc-dc converters optimized for railway traction, rolling stock apps

External References

Medical Design Briefs, “Every Drop Counts: Designing Motors to Optimize Home and Ambulatory Infusion Pumps”

Electrical Desk, “Different Types Of Traction Motors”

Everything PE, “What is an Electric Vehicle Traction Motor?”

Wikipedia, “Traction Motor”

Springer, “Vehicle Traction Motors”

The Railway Technical Website, “Electric Traction Control”

ABB, “ABB traction motors — Light rail vehicle (LRV)”

ABB, “Let’s go electric now! Advanced e-mobility drivelines”

Monolithic Power Systems, AN047, “Brushless DC Motor Fundamentals”

Curtis-Wright, “CWTI-D420 New Generation Dual Traction Inverter Sales Brochure”

Curtiss-Wright, “Traction Inverters Data Sheet”

Texas Instruments, “Technical White Paper Design Priorities in EV Traction Inverter With Optimum Performance”

Texas Instruments, “Design Priorities in EV Traction Inverter with Optimum Performance”

Texas Instruments, “Enhance the Design of HEV/EV Traction Inverter Systems Using Isolated IGBT and SiC Gate Drivers”

Leave a Reply